Industry 4.0 Without Fear: Modular MES Software Lets You ‘Start Simple’ and Add on Later

‘Don’t be afraid of MES.’ App-based platform can start with monitoring just downtime and cycle time on a few machines and add machines and functionality later.

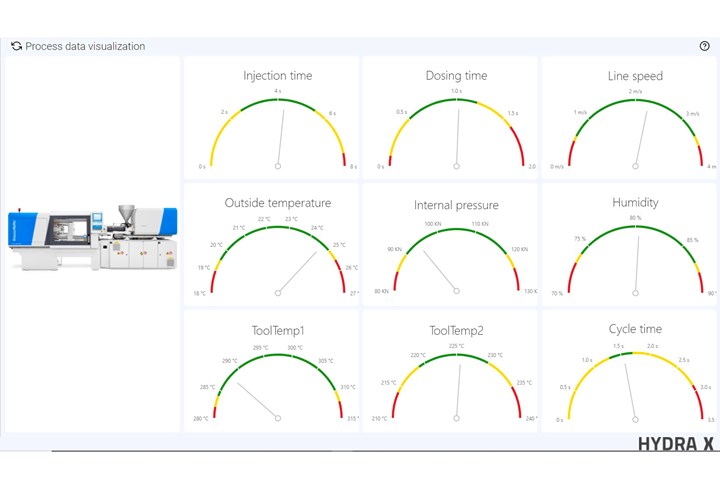

“Visibility” of processes and production is the key value of MES. MPDV’s Hydra X system is modular, allowing a user to “start simple” with one or two machines, just tracking uptime/downtime and cycle time and adding machines and functionality later on. (Photo: MPDV USA Inc.)

Processors who seek better visibility into their plant operations to clear bottlenecks and improve productivity have had a choice between elaborate, full-featured MES and MRP systems or trimmed-down “MES-lite” machine-monitoring systems that are simpler, quick-to-launch systems that require little employee training or installation effort. A company that positions itself somewhere in between these two poles is MPDV USA Inc. in Orland Park, Ill., near Chicago (mpdv.com/en). MPDV may be relatively unfamiliar to U.S. processors, but the firm was started in Germany in 1977 and has been in the U.S. for 15 years. It is said to be well known in plastics in Germany, though also active in metalworking and automotive, as well as medical devices, textiles and food/beverage production. All told, MPDV reportedly has 80,000 machines connected globally, including both primary and secondary or auxiliary equipment.

MPDV’s flagship product, Hydra X, was introduced in 2021 as “the next generation of MES.” It’s key distinction is that it is “not monolithic,” but a “platform-based” modular system. The foundation is MPDV’s Manufacturing Integration Platform (MIP), to which can be added over 120 manufacturing apps (“mApps”) from MPDV and a partner network of more than 35 software vendors. These are available through MPDV’s own app store, called the MIP Marketplace.

“Don’t be afraid of MES,” according to Quentin Cate, MPDV USA’s director of sales and marketing. With this modular structure, a user can start simply with monitoring just uptime/downtime and cycle time on one or two machines or manufacturing lines. Then it’s possible to add more machines or lines and functionality via mApps such as MPDV’s FEDRA Advanced Planning System (APS), for scheduling simple or complex jobs and projecting material needs. The wide variety of mApps takes Hydra X “far beyond a classic MES,” Cate says, with functions such as AI-based setup-time prediction, AI-based capacity-utilization analysis by shift, assembly management and control, energy demand planning, FMEA failure mode analysis, inspection planning and inspection equipment management, human resources (HR) management, maintenance management, materials management and predictive planning, SPC and quality management, supplier evaluation, time & attendance, tracking & tracing, complaint management, workforce planning. If users already have their own systems for ERP, PLM, scheduling, etc., MPDV’s platform is designed to interface with them. (In 2020, MPDV joined the Open Industry 4.0 Alliance, which has 100 members.)

Another simplifying feature of Hydra X is that the same basic interface is used for both the shop floor and manager’s office, with screens easily configured for different users. The system is also available on mobile devices, and data can be exported to Excel for additional analysis.

Related Content

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

-

Open Automation Enables Flexibility in Chemical Recycling

Software-defined equipment control systems can be duplicated, transferred and scaled with ease.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.