Machine Builders Join Forces On Novel ‘Direct-to-Sheet’ Technology

PTi, Farrel Pomini team on sustainable technology platform that combines compounding and sheet extrusion at extremely high filler loadings.

Two machine builders have formed a strategic alliance that will give sheet processors an altogether new option to produce highly filled structures as part of the compounding process. Processing Technologies International (PTi) and Farrel Pomini announced the new joint technology effort, called Direct-to-Sheet (DTS) Compounding, in late March.

The venture integrates Farrel Pomini mixing technologies—notably the firm’s Compact Processor (CP)—with PTi roll stands and related downstream technologies for sheet. The system will permit sheet to be extruded from a wide range of polymers with filler loadings of 60-70% or more, states Dana Hanson, president of PTi. Applications include foam packaging and a gamut of industrial end uses for sheet, such as automotive. The system can produce roll stock or be integrated in-line with a thermoformer. Depending on machine size, the DTS system can run at rates from 2200 lb/hr to more than 10,000 lb/hr.

Hanson and Matt Banach, PTi’s v.p. of sales and marketing, see big opportunities for DTS at large, multi-plant sheet processors whose product lines are under environmental siege. This is particularly the case in cups and other packaging products that rely on foam. States Hanson, “The DTS is a multi-resin solution that address sustainability and recycling issues that our customers face every day with bans on foam cups and the like. When a processor is running sheet that has 60-70% talc or calcium carbonate fillers, they are actually running 60-70% earth.”

Adds Banach, “There has been a stigma building against foam for years. Processors that produce foamed products are under a lot of pressure from environmentalists. We read about bans against their products on a regular basis. Foam is attractive because it allows a processor to reduce the amount of polymer needed for a given product. And with DTS they can achieve that same goal with a more sustainable solution.”

Mineral-filled packaging has been in the market since the 1990s, when Mobil started making talc-filled PP trays. A large fast-food company also used a 50% mineral-loaded black lower tray on its takeout packaging.

What reportedly sets this technology apart from twin-screw compounders utilized by sheet and other extrusion processors is the relative ease with which the polymer can be filled. According to Hanson, co-rotating twin-screw compounders can accommodate about 15-20% mineral filler by volume through a single side feeder. Anything above that level requires additional side feeders, which Hanson states adds cost, complexity, maintenance concerns, and housekeeping issues to the process. This applies regardless of whether the twin-screw compounder is producing pellets, sheet, or other parts, Banach adds.

But with DTS, material is fed to the mixing station of the CP through a single feed opening. “The single-point feed opening eases formulation control and provides ‘housekeeping containment’ compared with multiple feed locations characteristic of twin-screw compounders,” states Hanson. Feeders dosing abrasive fillers also tend to wear quickly, he explains, while components on the CP can last up to three years or more. “Also, the DTS technology has an ROI that can be measured in months vs. years,” says Hanson. The DTS system will be available to sheet processors as a fully integrated package, states Banach.

HOW THE COMPACT PROCESSOR WORKS

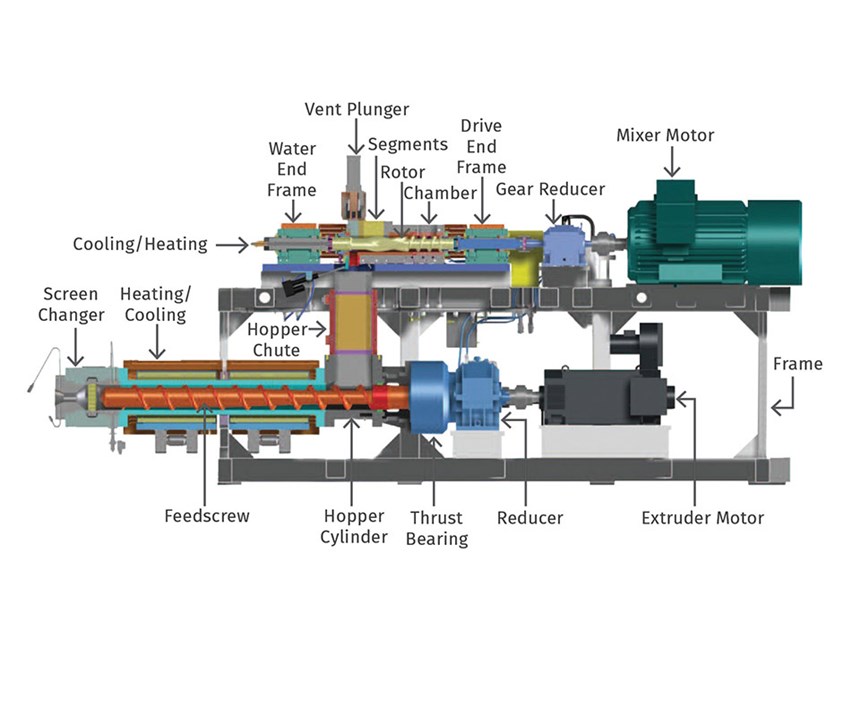

Farrel Pomini introduced the CP in the 1980s. Derived from the machine builder’s iconic continuous mixer, the CP is a two-stage machine that combines non-intermeshing twin rotors and a pressure-generating single-screw extruder on a common frame, fully wired, piped and pre-tested prior to installation, explains Paul Lloyd, the firm’s v.p, and business-unit director. The machine is designed specifically for highly filled, highly pigmented materials. Now in its second generation, Lloyd says there are roughly 300 CPs operating globally, with about 200 of those running in the U.S. With a few exceptions, the machines are installed at compounding facilities.

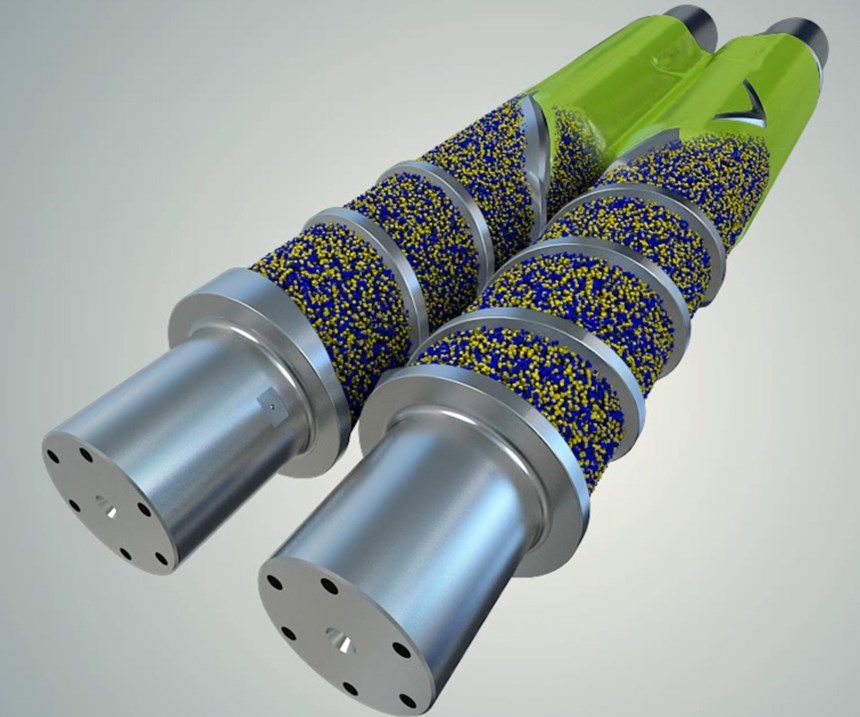

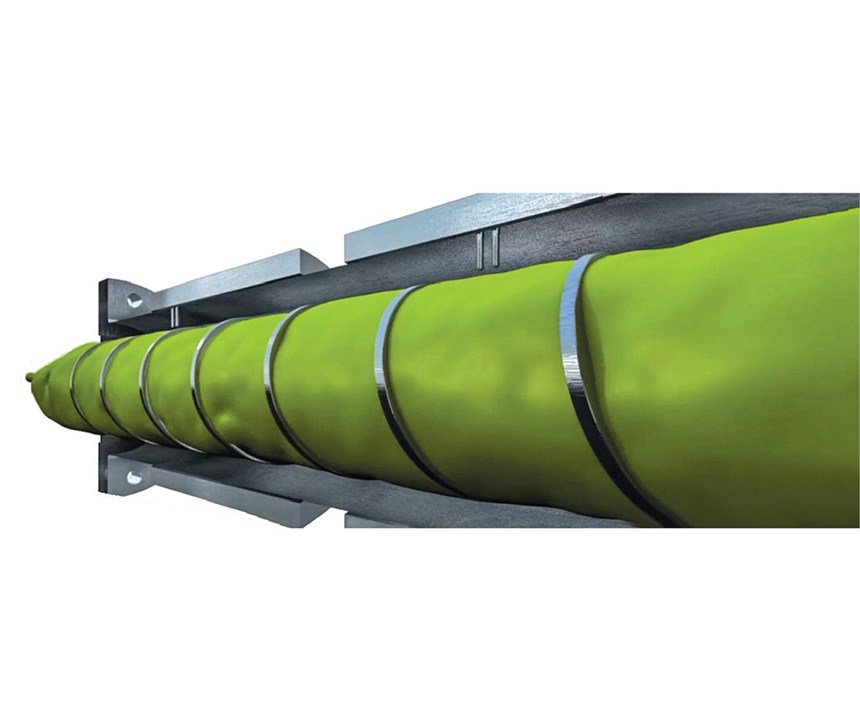

The CP is outfitted with a machine-mounted system that can control the mixer, extruder and all upstream and downstream systems from a single point. It can run a wide range of materials in the form of pellets, powder, flake, and liquid. In the mixing section, the two-lobe, elliptical, counter-rotating, non-intermeshing rotors have forward and reverse pumping wings that are said to facilitate distributive mixing through longitudinal forward and backward flow patterns. The rotating lobes also push material side-to-side between the rotors. Pigments and fillers are incorporated and dispersed as a result of intense shear imparted to the mixture as it flows multiple times in the gap between the rotor tip and housing.

Mixing is achieved at residence times much shorter than with other technologies, says Lloyd, as the standard mixing section has a 6:1 L/D ratio. This results in lower melt temperature and reduced overall energy consumption, producing compounds with low heat history and minimal degradation. The mixing chamber can be both heated and cooled to facilitate heat transfer and maintain melt viscosity for effective mixing. An adjustable gate valve at the end of the mixing chamber can control residence times. The mixing chamber features a clamshell barrel to facilitate cleaning.

Material from the mixing chamber is gravity fed through an enclosed connecting chute to the single-screw extruder. The extruder features a compression screw designed for pumping, resulting in minimal temperature rise of the compounded material. The extruder comes standard in a 11:1 L/D, with 17:1 available if venting is necessary, says Lloyd. The extruder head assembly can connect to a screen changer. For sheet applications, the line will also be equipped with a gear pump.

The CP is available in seven different sizes, with CP Series II models 1000, 2000, 2500 and 4000 being the most likely options for sheet processors (the model number represents the output capacity in kg/hr).

For packaging applications, PTi says the system will include its G-Series Roll Stand.

Related Content

Consistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreLatest Data on Bottled Water Shows Continued Strong Growth

Bottled water’s volume surpassed soft drinks for the first time in 2016 and has done so every year since.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More