Medical-Grade TPEs Bond Effectively to Copolyester

Joint testing by Teknor Apex and Eastman showed Medalist TPEs overmolded onto Eastman Tritan copolyester yielded durable bond for grips, gaskets, and other soft/rigid items

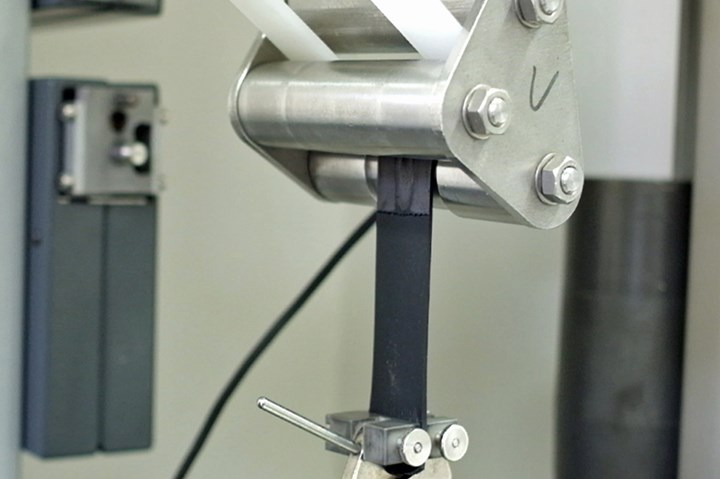

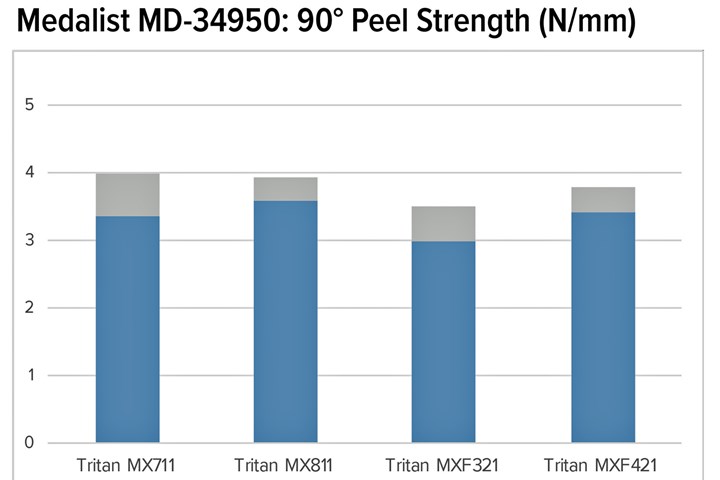

Teknor Apex and Eastman, both leading plastics suppliers to the medical device industry, have demonstrated a strong, chemical-resistant bond between TPEs and a clear copolyester substrate known for its toughness and chemical resistance. In 90-degree peel tests of test specimens produced in a two-shot molding process, three Medalist medical-grade TPEs from Teknor provided durable bonds to four of Eastman’s Tritan copolyesters.

Specifically formulated to adhere to copolyester and other engineering thermoplastics, the Medalist compounds demonstrated high levels of peel strength. The peel tests that showed high peel strengths with adhesive failures demonstrate excellent Tritan TPE overmolding performance. The combination of high peel strength and adhesive failure is considered desirable for overmolded applications. The bond strength between Medalist TPEs and Tritan exhibited very little loss even after soaking test samples for 48 hours in disinfecting chemicals, including a 70% isopropyl alcohol, Clorox bleach, and a 20% intralipids solution, which is a fat emulsion used as an intravenously administered nutrient.

Medalist compounds tested included three grades: MD-34940, MD-34950, and MD-34959, with Shore A durometers of 42, 50, and 59, respectively. Tritan grades MX711, MX811, MXF321, and MXF421, provided a good range of physical properties. All three Medalist compounds in combination with all four Tritan resins showed very little loss of bond strength after chemical exposure.

Overmolding TPEs onto copolyester offers medical device designers a combination of hard and soft materials that are advantageous in medical components. Soft TPEs are desirable for grips, gaskets, seals, and soft-touch elements on rigid medical housings and other components.

Said Dr. Yubiao Liu, Eastman’s global medical technical platform lead, “By combining Medalist TPEs and Tritan copolyesters, manufacturers can improve the ergonomics, aesthetics, or functionality of medical devices. The combination of soft TPEs with rigid copolyester substrates can enhance grip, add texture or comfort, yield a tight seal, or provide damping characteristics.”

Medalist TPEs combine the performance of thermoset rubber with the processing ease of thermoplastics, making them superior alternatives to silicones, PVC, and TPUs, noted Ross van Royen,Teknor Apex’s senior market manager, “We have developed Medalist TPEs to meet the most stringent requirements of the healthcare industry and produce them in multiple ISO-13485-certified facilities with only FDA-listed food-grade ingredients. All grades are biocompatible in accordance with ISO-10993-5, are RoHS and REACH SVHC compliant, and contain no phthalates, latex proteins, or BPA.”

Related Content

-

GEON Performance Solutions Buys PolymaxTPE

Combined company aims to be global leader in thermoplastic elastomers.

-

Fast-Cycling Selective Laser Sintering System

Nexa3D announced the QLS 260 for metal and polymer production.

-

Medical Grade TPEs for Biopharmaceutical Tubing

Teknor Apex expands its Medalist TPE portfolio.