PHA Production Capacity Projected to Grow Tenfold

A new report projects this bioplastic family is set to reach significant milestones and in just six years.

A new market report jointly published by the Global Organization for PHA (GO!PHA)https://www.gopha.org/ and the nova-Institute projects that production capacity for the PHA family of bioplastics will growth by tenfold and only in six years. “Mimicking Nature—The PHA Industry Landscape. Latest trends and 28 producer profiles,” is authored by professor Jan Ravenstijn, who has been working intensively on the topic of PHAs for 20 years, is co-founder of GO!PHA and the author of numerous publications.

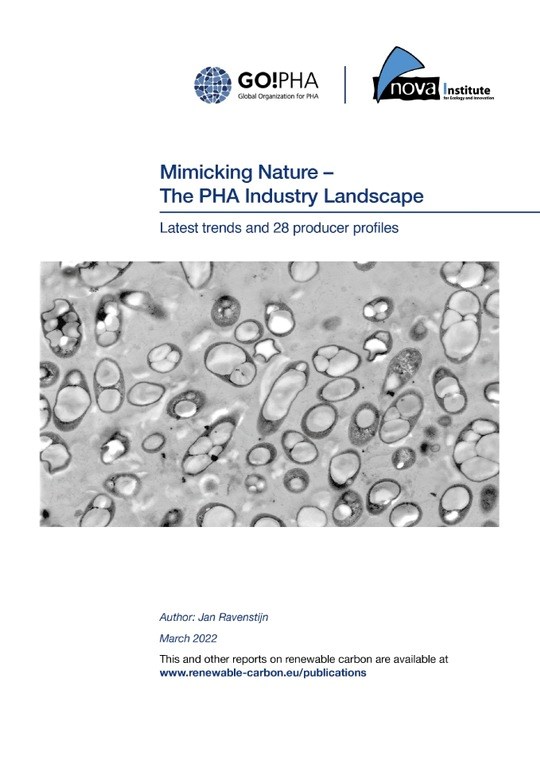

The author describes natural PHAs as a class of materials that are both biobased and biodegradable, similar to other materials that have existed in nature for millions of years such as cellulose, proteins and starch. PHAs are produced by an extensive variety of microorganisms through bacterial fermentation. She sees the potential of PHAs as enormous, noting that due to the high performance, biocompatibility, biodegradability and green credentials, the PHA family has a large design space and accommodates a wide range of market applications, as a broad variety of different polymers can be produced and blended.

Photo Credit: GO!PHA and novi-Institute

Photo Credit: GO!PHA and novi-InstituteAt the same time, the author notes that this family of bioplastics has encountered highs and lows over the last 20 years, with several expansions and scale-up plans postponed or even cancelled. She attributes this to such factors as the challenges of technology scale-up, product and application development needs, along with an underestimation of how much time it takes for a new polymer-platform to penetrate the market and the time it takes for previously unconnected disciplines to understand each other for the benefit of successfully addressing all opportunities.

However, the momentum for this new polymer platform is rapidly changing for the better. The author reports that at the end of 2021, the installed manufacturing capacity of PHAs up and running was approximately 105.8 million lb/yr, based on information she obtained from the companies in this report. Moreover, capacity expansions have been announced and there are numerous new plants under construction, which combined aim to increase the manufacturing capacity of PHAs to about 1.3 billion lb/yr by 2027.

Most companies featured in the report are or were startups when they began their natural PHA activities. Only six companies are already established in the market. “Developing new products to create a sustainable future for polymers, respecting the environment and our future generations is the motivation for most parties working on this new materials platform. They are in tune with a rapidly changing plastics industry,” she reports.

“Mimicking Nature – The PHA Industry Landscape. Latest trends and 28 producer profiles” is available at http://www.renewable-carbon.eu/publications starting at 1,500 €.

Related Content

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

-

How to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.