Pittsburgh International Airport to Establish an Additive Manufacturing Production Campus

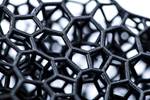

The planned development, called Neighborhood 91, will be the first-ever cluster strategy with a production focus of 3D printing.

Pittsburgh International Airport announced plans for Neighborhood 91, the reportedly world’s first development to condense and connect all components of the additive manufacturing/3D printing supply chain into one production neighborhood concept.

PIT Airport CEO Christina Cassotis hands Arencibia president Joe Arencibia a 3D printed key at an event announcing Arencibia as the first tenant of Neighborhood 91.

Neighborhood 91, developed in conjunction with the University of Pittsburgh, is the first development of the 195-acre Pittsburgh Airport Innovation Campus and will be built adjacent to the airport terminal and runway. The first tenant – argon gas supplier Arencibia – has committed to be the anchor tenant.

The Barnes Group Advisors (TBGA), an independent advanced manufacturing engineering consultancy, released an impact study revealing the overall economic benefits of an Additive Manufacturing production campus for the Pittsburgh International Airport.

The TBGA report substantiated that a cluster concept like Neighborhood 91 can act as a catalyst for AM industrialization and innovation. Multiple numerical data models with relevant industry data were complemented by economic theory to analyze the impact. Five key impact areas were identified:

· Reduction in production costs – 25% for parts and 30% for powder

· Simplified supply chain with 80% reduction in manufacturing lead time and 80+% reduction in transportation cost and miles for powder to part production

· Workforce development and R&D boost productivity and innovation

· Agglomeration economies and labor market pooling for reductions in learning curves and under-utilized equipment

· Reduced energy consumption and emissions

Observing the many cost impacts of a concentrated AM production campus, TBGA ADDvisor Services Leader and report co-author, Laura Ely, commented, “the current AM production supply chain is fragmented. This study validates that Neighborhood 91’s centralized campus will significantly reduce cost and the need to manage parts across a dispersed supply chain.”

According to the study, the industrial park at Pittsburgh International Airport will create nearly 6,000 jobs over the next decade and will generate about $2.2 billion in wages over that same time period.

TBGA Founder and Managing Director, John Barnes, said that the campus can help with workforce development.

“A cluster does two key things: It enables process owners to focus on developing and optimizing their core process, and it creates a skilled regional labor pool,” he said.

Related Content

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

DuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.