Plastic Mold Buyers Guide to Be Updated

After nearly 25 years, the plastic industry’s guide for buying molds—Customs and Practices of the Moldmaking Industry—is being updated by the the Plastics Industry Association (PLASTICS), in conjunction with the moldmaking sector.

Last revised in 1996, the 21-page guide was originally drafted in the early 1980s by the Moldmakers Division of the Society of the Plastics Industry (SPI), now PLASTICS. It codified what are now widely accepted and used terms and definitions like Class 101 molds, as well as guidelines for the procurement process

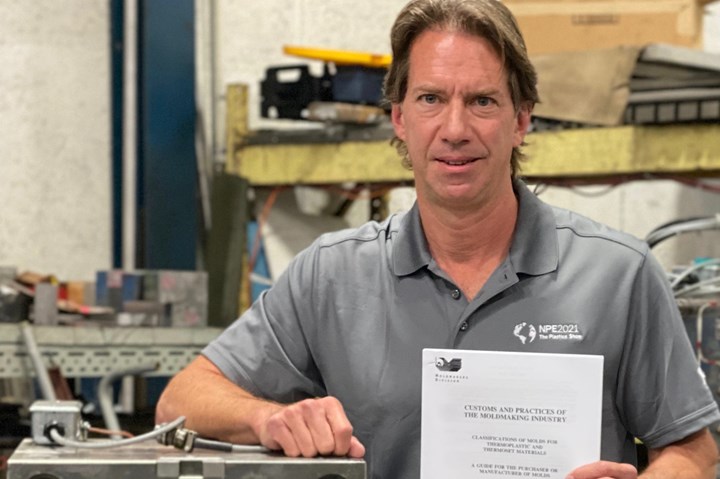

Glenn Starkey, president of mold component and tool monitoring supplier Progressive Components, is leading the task force to revise the guide, along with Toby Bral of MSI Mold Builders (Cedar Rapids, Ia.) and Wally and Camille Sackett of Accede Mold & Tool (Rochester, N.Y.). Starkey is also the current chair of the Moldmakers Division of PLASTICS’ Committee on Equipment Statistics.

The task force, which began meeting in September, is collaborating with Jennifer Jones, PLASTICS’ director of industry standards. At this time, the group meets every three weeks to review the guide with Jones.

When it was first published, the guide was intended to help avoid misunderstandings and conflicts between toolmakers and tool buyers in the mold procurement process. The manual addresses topics such as mold classification, providing mold data sheets, practices of making payments, receiving progress reports and arranging a mold’s delivery.

Rather than scrapping the original content, Starkey said the work of the taskforce will primarily involve heavy editing and updating. At present, the guide has outdated references to everything from N.C. (numerical control) tape, mylars, hobs, and mandrels to pink carbon copies.

Practices for mold payments, mold qualification and warrantying mold performance are being reviewed. The revised guidelines also will have an updated mold data sheet, which serves as a checklist of the mold buyer’s needs and is used for quotations, and a progress report template for providing status during the various mold building stages.

Glenn Starkey, president of Progressive Components, is leading the task force to revise the guide.

An initial draft will be circulated to a consensus group once the task committee reviews the document’s structure and content. The consensus group consists of mold buyers and makers within PLASTICS. The same committee will also seek input from members of the American Mold Builders Association and the industry at large. While there isn’t an exact target completion date for the guide, the group expects to seek industry feedback in early 2021. The task force is also reviewing the mold finish guides.

In an interview with Plastics Technology, Starkey said the guide has two primary aspects—describing the procurement process and setting classification. “What are practices of inquiry for quote, placing an order, setting deliveries, setting payments—business matter stuff,” Starkey said. “It describes how this interaction goes. It’s not like buying 100 sprockets—you’re buying a quantity of one and no two are alike.”

The classification element, meanwhile, formalizes expectations for a tool. “Instead of saying something subjective, like, “I want a really top-notch mold,’ and on the other end: cheap and dirty—this gives it some definition.”

Related Content

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.