Sepro Group Launches Virtual Showroom

The robot and automation supplier has assembled an array of equipment and technical expertise in a ‘Virtual Showroom’ that will be live at least through 2020.

In response to the cancellation of all major plastics trade fairs this fall due to the coronavirus pandemic, robot and automation supplier Sepro Group has created a virtual showroom featuring on-demand technical expertise and robotics that can be viewed in three dimensions by visitors. The company plans to keep the showroom online at least until the end of 2020, to help it “keep in touch with our clients, our partners and all who seek to automate their production lines,” the company said in a release.

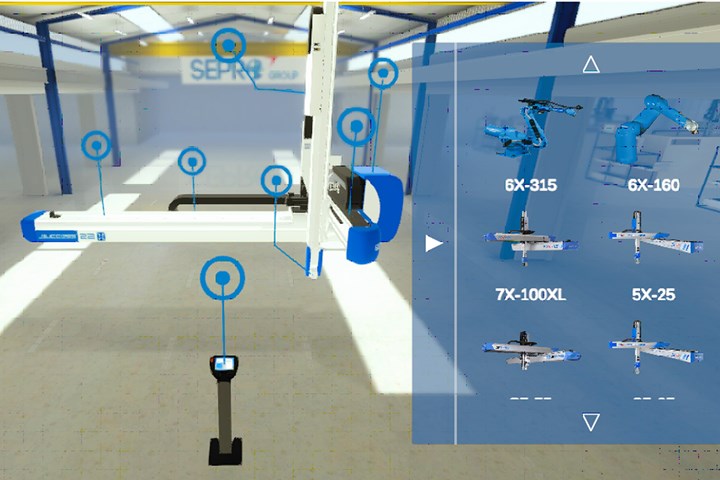

Robot and automation supplier Sepro Group has set up a Virtual Showroom for customers to review and interact with its line of robotics.

Sepro says the entire Sepro robot portfolio is featured including, the completely redesigned Success Range of 3- and 5-axis general-purpose robots, as well as 3- and 5-axis robots in all sizes. In addition, 6-axis robots, co-developed with industry leaders Yaskawa Motoman and Stäubli, will also be featured, as will Smart data services including Live Support, the company’s live hotline support feature designed to reduce downtime.

Visitors can click into a 3D virtual display that allows them to study Sepro robots, rotating them through all angles and perspectives. These displays feature brief text descriptions of key features and capabilities, and a menu bar lets users choose which robots to examine.

Another section of the showroom allows visitors to schedule socially-distanced face-to-face discussions with Sepro technical experts on seven different topics about robots and automation in the plastics industry, or simply to share ideas about current and future projects.

Visitors can schedule presentations on the following subjects:

- How to reduce downtime with preventive maintenance.

- Fast troubleshooting best practices and tools.

- What EOAT do I need for my application? Review My Gripper: Sepro’s EOAT component catalog.

- New affordable robots: Success and Success Line X.

- Why multi-axis (5- and 6-axis) robot solutions are more flexible.

- Solution by Sepro: the Sepro approach to complete turnkey automation systems.

Related Content

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

-

AI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.