Stratasys Focusing on Sustainability for 3D Printing Industry

Stratasys becomes founding member of Additive Manufacturer Green Trade Association.

Stratasys Ltd. recently announced several initiatives to place a greater emphasis on sustainability in 3D printing. The company has established its ‘Stratasys Sustainability’ function and appointed Rosa Coblens as vice president of sustainability. Stratasys said a commitment to a circular economy, climate action, and social impact is paramount.

“The new global economy requires companies to adapt and overcome unexpected challenges, while maintaining a commitment to environmental stewardship,” said Stratasys CEO Yoav Zeif. “Stratasys is well-positioned to provide production and manufacturing solutions that are resilient, empower local supply chains, and most importantly save lives. For example, during the pandemic we were able to repurpose our ecosystem to support the design, manufacture and delivery of vital personal protective equipment and ventilator parts to the healthcare industry.”

Zeif added, “Beyond the global pandemic, climate change is a growing worldwide concern. It is our mission to translate our leadership in 3D printing into mindful business applications for our customers – where less waste is produced, and more value derived from the digital processes that drive our manufacturing solutions. This approach is aimed at assisting our customers in reducing their carbon footprint, with less dependency on mass shipment of inventories and parts, shortening and localizing supply chains across industries such as aerospace, automotive, healthcare and consumer products.”

To advance its commitment to sustainability, Stratasys joined the Additive Manufacturer Green Trade Association as a founding member, with Coblens serving on the AMGTA Board of Directors. The AMGTA is a new global trade organization launched in November 2019. The AMGTA is a non-commercial, unaffiliated organization open to any additive manufacturer or industry stakeholder that meets certain criteria related to sustainability of production or process. Part of the AMGTA’s mission is to commission research that highlights the sustainable uses of additive manufacturing.

Stratasys also identified four U.N. Sustainable Development Goals (SDGs) as the cornerstones of its purpose-driven sustainability efforts. Measurable goals are being designed as part of Stratasys’ 2022 focus areas:

- Responsible Consumption and Production: The world continues to use natural resources unsustainably. Ensuring more responsible consumption and production patterns includes the environmentally sound management of chemical waste, the disposal of waste generally, and the efficient use of production materials. Additive manufacturing can be a more efficient production method, alongside a growing use of recycled and renewable materials. Stratasys is committed to innovation in reduced waste, reused materials and recycled packaging.

- Industry, Innovation and Infrastructure: Industrialization benefits economies around the world, creating jobs and wealth; it makes information and communications accessible through technology, it promotes inclusive research and innovation, and supports entrepreneurship. Stratasys intends additive manufacturing to benefit people worldwide, enabling designers, engineers and manufacturers with local, on-demand capabilities that empower companies and organizations of all sizes to improve quality of life everywhere.

- Climate Action: Climate change continues to impact the frequency and severity of natural disasters, and not enough action is taken to move towards net zero carbon emissions. Such targets become easier to achieve by reducing global shipping, and by using more efficient, digital manufacturing methods. Stratasys is committed to reducing not only its own carbon footprint but to making it easier for customers to do so when using Stratasys’ products, as well.

- Quality Education: As a company powered by the possibilities of innovation, Stratasys is committed to ensuring inclusive and equitable quality education and learning opportunities for everyone, advancing ‘learning by making’ opportunities, and leveraging our technology to empower students – the workforce of tomorrow. This means ensuring everyone has the literacy and relevant technical skills for rewarding careers. Stratasys both markets solutions to educators and advocates for them.

Stratasys recently joined the Additive Manufacturer Green Trade Association as a Founding Member.

Related Content

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

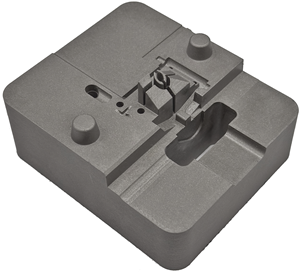

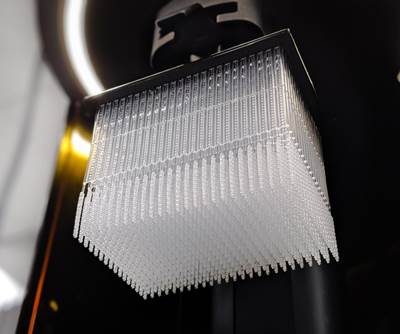

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreRead Next

20 Good Things to Come Out of 2020—Part 5

Additive manufacturing has emerged as the supply chain hero in many ways during the COVID-19 pandemic. While the recycling industry continues its push for a Circular Economy.

Read MoreWhat Is the Circular Economy?

In this video from K 2019, hear NOVA Chemicals, TOMRA, Covestro, Rapid Granulator and SABIC each discuss plastics’ role in the circular economy.

Read MoreKey Additive Manufacturing Trends to Watch in 2021

EOS, HP, Carbon and Essentium give a preview of what to expect from additive manufacturing in 2021.

Read More