Additives: Latest Tests Show High Performance of New Liquid Additive in 100% Polyolefin Regrind

Riverdale Global’s ‘strenghthening’ additive shown to boost properties of PP and HDPE post-consumer recyclate while enhancing flow and part consitency.

Key physical property tests on a liquid ‘strengthening’ additive launched last year by Riverdale Global, Aston, Penn., which were conducted by the company in cooperation with a molder of packaging containers has demonstrated that +Restore liquid additive is even more effective than was originally claimed for improving the performance of plastics regrind based on post-consumer waste.

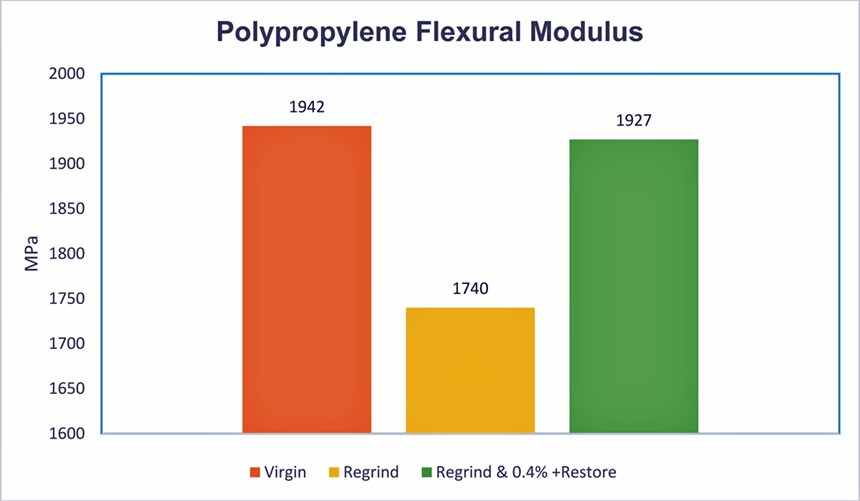

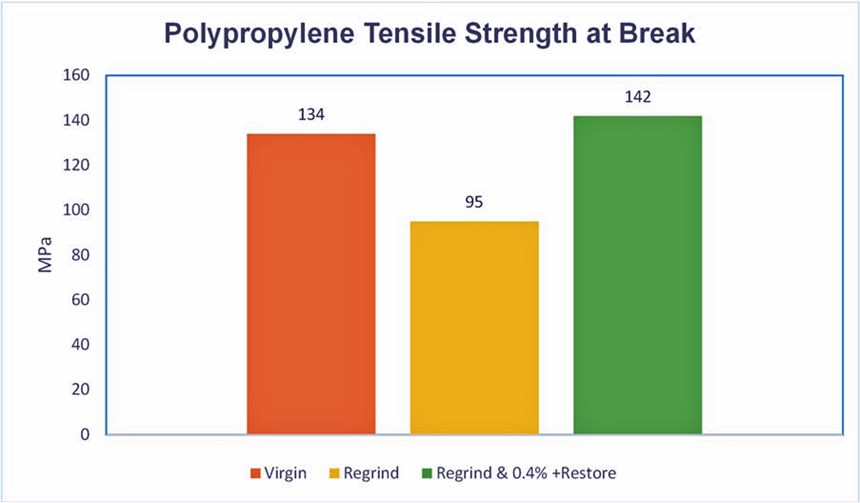

The test results indicate that at relatively low usage levels, the +Restore enables processors running 100% post-consumer PP or HDPE to obtain products with virgin-like properties. A sampling of test results comparing 100% Below are some test results comparing virgin PP with 100% PP regrind containing 0.4% +Restore additive showed:

▪ Flexural Modulus. Regrind PP tested at 99% of virgin PP.

▪ Strain at Yield. Regrind PP tested at 89% of virgin PP at 106%.

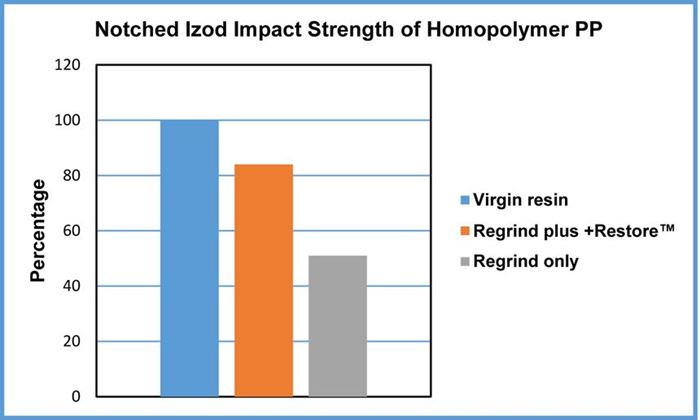

▪ Izod Impact Strength. For regrind PP modified with +Restore additive, this property tested at 16% less than that of virgin PP, versus unmodified regrind at 49% less.

Says technical sales manager Jared Arbeter, “These test results and similarly encouraging data for HDPE show that plastics processors can use the +Restore additive to meet sustainability goals by actually upcycling post-consumer waste, eliminating most, and in some cases all, of the property losses typically incurred in recycling.”

Moreover, +Restore was also shown to improve part consistency in comparison with untreated recycled material, according to Arbeter noted. As measured by standard deviation in a range of physical property tests, for example, HDPE regrind with 3% white concentrate exhibited 50% or more decreases in part variation when it contained 0.4% of the +Restore additive.

Arbeter notes that there are also other benefits provided by the +Restore additive, according to Arbeter. “Because the additive has an affinity for the base polymer, it acts as a lubricant, enhancing melt flow. In addition, the +Restore molecule has a functional group that readily reacts with pigments, fibers, or fillers in the resin, while a different segment of the same molecule is designed to couple with the polymer; as a result, it forms a strong bond between resin and filler without compromising flexibility.”

The +Restore additive can be used in all thermoplastic processes, alone or in a blend with Riverdale Global’s liquid colors. Typical usage rates are in the 0.1 to 0.5% range.

Related Content

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Extrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.