AI Software Extended to Multiple Fanuc Robots

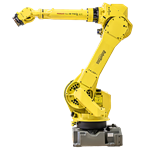

Micropsi Industries MIRAI software allows the Fanuc robots, including cobots, to be trained via hand guiding, and it lends “hand-eye” coordination for difficult-to-automate jobs.

Micropsi Industries’ AI-based MIRAI software MIRAI is now compatible with numerous robots produced by Fanuc, which joins Universal Robots in this compatibility. Micropsi says MIRAI will allow Fanuc customers to add hand-eye coordination to multiple Fanuc robots, including cobots, allowing them to take on difficult-to-automate functions such as cable plugging and assembly.

Using AI, the MIRAI controller generates robot movements directly and in real-time so that robot skills are trained, not programmed, through human demonstration. To train a robot, a human repeatedly demonstrates a task by manually guiding the robot by the robot’s wrist. The recorded movements are then transformed into a repeatable skill.

As an example of a difficult-to-automate task that the MIRAI technology makes feasible, Micropsi points to cable plugging applications such as flat ribbon cables for electronics or automotive connectors. These typically require a high degree of flexibility to accommodate shape instability, making it a difficult task for any robot. Micropsi Industries plans additional automation projects that will expand the range of applications for Fanuc’s industrial robots.

The MIRAI software lends Fanuc robots hand-eye coordination, making more complex automation tasks possible.

Photo Credit: Fanuc

Related Content

-

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

-

Five Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).