Application Records, Displays all Sustainability Relevant Process Data

KraussMaffei (KM) says new software provides in-depth process data by capturing up to 500 machine signals in real time for carbon footprint measurement.

Working together with auxiliary equipment supplier Motan, KraussMaffei says it has developed software to capture all sustainability related process data, helping processors account for the amount of carbon dioxide saved by recycling materials versus using virgin resin, among other capabilities.

Together with Motan, digital APC plus platform has been optimized to show the energy consumption of each process step, enabling processors to record and improve upon their energy consumption. Further, KM says APC plus has been adapted to the processing of reclaimed material and can help reduce production scrap by automatically adjusting to changing conditions during molding. During start-up as, KM say nominal process values are reached much faster, decreasing start-up scrap. KM says its dataXplorer captures up to 500 machine signals in real time for carbon footprint measurement, with any deviations from the pre-defined tolerance ranges detected instantly.

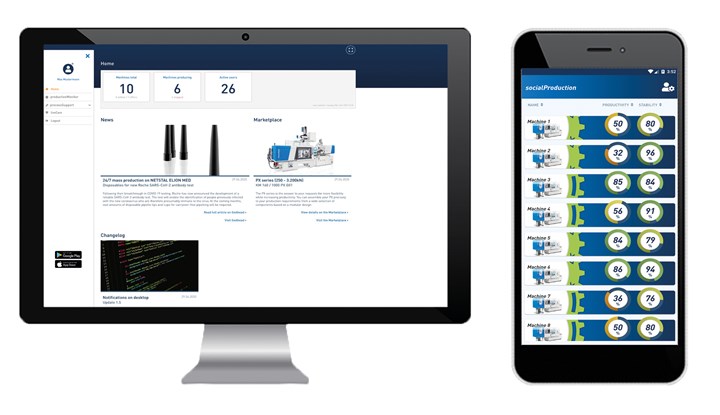

KraussMaffei’s digital assistant portfolio can help processors who want, or need, to be more cognizant of their environmental footprint, with offerings including liveCare, processSupport and productionMonitor, which are all part of its socialProduction suite of products. In addition, the company puts forward its e-commerce platform—pioneersClub.

KM notes that in the European Union plans are in place to introduce a digital product passport that would require manufacturers and OEMs to document, among other things, the materials used for each product and how they were processed. KM says the digital products it currently offers would enable processors to start moving in that direction.

A smartphone app and a web application for PC or tablet are available for KM’s socialProduction.

Photo Credit: KraussMaffei

Related Content

-

Exhibitor Registration Opens for K 2025

Exhibitor registration for the triennial event, which will take place Oct. 8-15, 2025, in Düsseldorf, Germany, is open with a reservation deadline of May 31, 2024.

-

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

-

Energy Efficiency in Focus at K 2022

As much as cycle time, kWh/kg was an oft-cited metric by injection molding machine suppliers at October’s big show.