At K 2022: Improved Automatic Process Control for PET Bottle Blowing

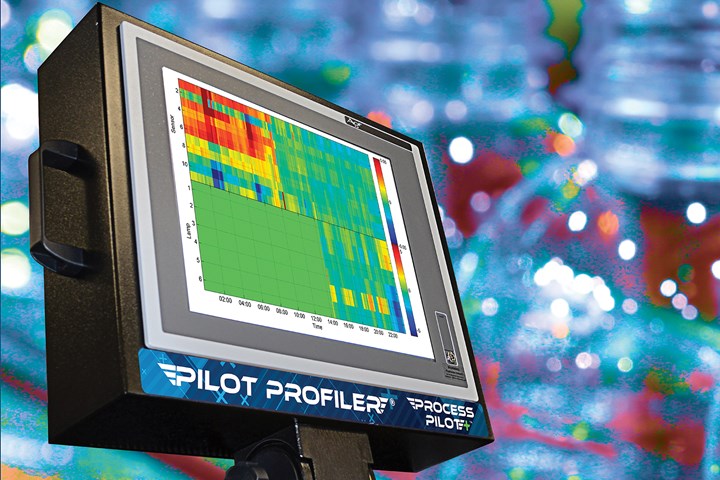

New Process Pilot+ from Agr International offers faster response and flexible goals for keeping PET bottles on spec.

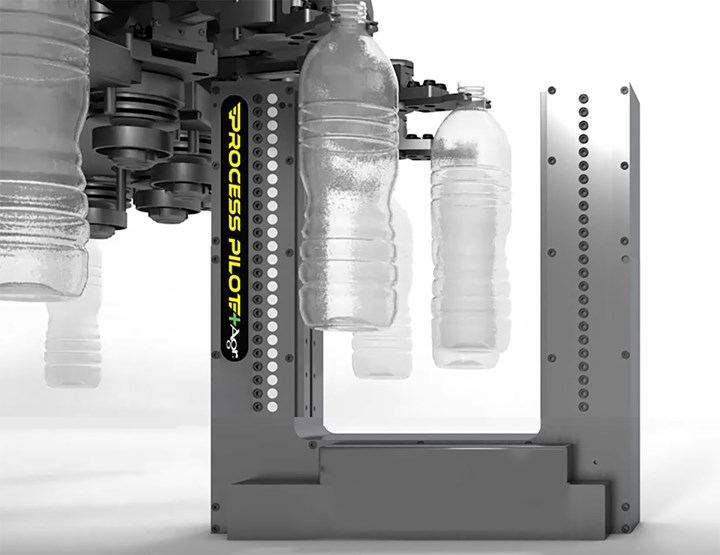

Multiple control loops in Process Pilot+ are said to correct process drift as much as 40% faster and enable startups to reach on-spec bottle production up to 65% faster. (Photo: Agr International)

At next month’s K 2022 show in Düsseldorf, Agr International is introducing an enhanced version of its Process Pilot system for automated process management of two-stage (reheat) stretch-blow machines for PET. Like the original version, the new Process Pilot+ uses bottle wall-thickness measurements from Agr’s Pilot Profiler inline QC instrument to adjust the machine settings to compensate for changes in the operating environment (temperature, humidity), the preform quality or the material (especially variations due to the presence of rPET). The new version incorporates multiple control loops that regulate slow-response processes such as oven temperatures separately from very fast-acting processes like blow pressure and timing. The multiple control loops allow the system to correct process drift as much as 40% faster and also enable startups to reach on-spec bottle production up to 65% faster.

In addition, a new, patented Value Performance feature answers the question: “How do I make the best bottle I can for the lowest cost?” This option lets the user specify a less-than-perfect level of wall-thickness distribution that is acceptable in return for reducing compressed-air usage or energy consumption or use of lower-quality preforms.

Agr International’s Pilot Profiler measures bottle wall-thickness distribution in line with stretch blowing to permit immediate process correction via Process Pilot+. (Photo: Agr International)

Agr International also plans to introduce a new portable wall-thickness gauge at the show. The company already offers a capacitance-type gauge and a magnetic gauge. The new instrument will incorporate multiple technologies and is designed to be versatile, lower cost and more durable than existing products.

Related Content

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

Exhibitor Registration Opens for K 2025

Exhibitor registration for the triennial event, which will take place Oct. 8-15, 2025, in Düsseldorf, Germany, is open with a reservation deadline of May 31, 2024.

-

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.