Automotive TPVs Formulated with Scrap

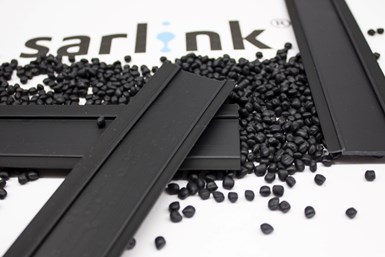

Latest addition to Teknor Apex Sarlink is offered with up to 40% post-industrial scrap. Can be extruded or molded.

Teknor Apex’s latest addition to its Sarlink line of thermoplastic vulcanites is RX 3100B. It was was developed to help automotive OEMs achieve sustainability targets by incorporating up to 40% post-industrial recyclate, depending on the hardness.

These multi-purpose TPVs are suited for injection molding, extrusion, overmolding and coextrusion with PP or other thermoplastic elastomers (TPEs). For these high-durometer grades, applications include the backbone or carrier for extruded seals, like in glass run channels, or boots, bellows, and other under hood components.

The two new grades available, an 84 Shore A and 94 Shore A, are based on the existing Sarlink 3100 Series technology, but contain 25% and 40% recycled content, respectively. The materials reportedly process and perform similarly to their virgin counterparts yet offer sustainability benefits such as reduced dependency on virgin petroleum-based plastic — ideal for OEMs looking to reach aggressive targets around the use of sustainable material content in vehicles. Sarlink RX 3100B TPVs are pre-colored black and can still be recycled in process or at the end of the product’s life cycle.

Photo: Teknor Apex

More Consistency

The use of PIR content vs. PCR is sid to provides for a more controlled and consistent raw material stream that can be used in extrusion-grade TPVs without issue. Teknor Apex treats recycled feedstocks like prime raw materials, and they are subject to the same quality assurance testing and must meet relevant specifications for use.

“At Teknor Apex, we recognize our responsibility as part of the value chain, to manufacture our products as sustainably as possible, while continuing to deliver more sustainable material solutions to the market. We collaborate closely with major brands to understand their sustainability goals and deliver relevant solutions,” says Scott Nakon, global automotive market manager.

He adds, “Our ongoing projects include new sustainable raw materials streams such as recycled and bio-based content, as well as carbon negative additives. Also, we plan to introduce new thermoplastic elastomers with up to 65% post-consumer recycled content later this year, as well as expand the Recyclon portfolio of recycled polyamide solutions.”

Related Content

-

GEON Performance Solutions Buys PolymaxTPE

Combined company aims to be global leader in thermoplastic elastomers.

-

Printable Thermoset Polyurethane

Chromatic 3D Materials launched ChromaMotive D65, designed for additive manufacturing.

-

Hybrid EPDM-TPE Adhesion Compounds for Automotive Industry

Kraiburg’s new compounds targeted to auto sealing and exterior sector applications and toolmakers.