Carbon-Fiber ABS for a Broader Range of FDM 3D Printers

Stratasys’ new FDM ABS-CF10 is the first thermoplastic composite material for its line of F123 Series 3D printers which combine FDM technology with design-to-print GrabCAD print software.

A new ABS-based carbon fiber material from Stratasys, Eden Prairie, Minn., is the first composite material launched by the company for its line of F123 Series 3D printers, which combine FDM technology with design-to-print GrabCAD print software..

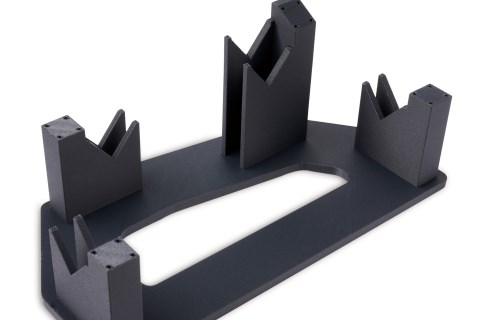

The company carbon fiber materials have proven extremely popular on the company’s industrial-scale FDM machines for a variety of end-use applications such as jigs, fixtures, and tooling. With FDM the newly launched ABS-CF10, Stratasys now makes carbon fiber much more accessible to the engineering and manufacturing community with high-performance F170, F270, and F370 3D—all part of the F123 Series of 3D printers.

FDM ABS-CF10, featuring 10% chopped carbon fiber, is said to make it a compelling alternative to metal parts. In fact, the material is 15% stronger and more than 50% stiffer than standard ABS, without the weight of metal, and reportedly can be printed with a high degree of accuracy. QSR Support water-soluble material makes it possible to 3D print intricate and complex parts without time-consuming manual support removal.

Stratasys’ internal analysis suggests the additive manufacturing market for polymer jigs and fixtures is expected to grow at a 14.2% annual rate between 2019 and 2023, to nearly $600 million, double the growth rate of the prior four years. With its FDM ABS-CF10 material, Stratasys is particularly focused on addressing applications in the aerospace, automotive, industrial, and recreational manufacturing industries. Parts applications include end effectors used with industrial robots, ergonomic aids such as lift assists and hand tools, and alignment fixtures on assembly lines.

Said Stratasys sr. v.p. of manufacturing Dick Anderson, “There is a reason why manufacturers are increasingly turning to 3D-printed carbon fiber materials. They are incredibly strong, versatile, and lightweight. We want to enable all our FDM customers to take advantage of those material characteristics. Introducing FDM ABS-CF10 is a significant step in growing 3D printing’s presence in the global manufacturing industry.”

The FDM ABS-CF10 material is scheduled to be available in April 2021, and orders are being taken now.

Related Content

-

Soft Prices for Volume Resins

While PP and PE prices may be bottoming out, a downward trajectory was likely for all other volume resins, including engineering types.

-

Tracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

-

Prices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.