Cartesian Robot Line Enhances Control, Increases Speeds and Boosts Takeout Functions

Absolute Robot has upgraded its Max series of full-servo top-entry robots upgrading its control, speed and takeout functions with the Y-Free capability.

Absolute Robot Inc. (ARI) Max series of full-servo top-entry cartesian-style robots now feature a control enhancement; increased traverse speeds; and the ability to handle more complex automation scenarios, which all serve to reduce overall cycle times.

Max series now has “Y-Free” robot takeout functionality, which can serve to reduce the amount of time the robot spends within the mold, ultimately cutting overall cycle time. The “Y-Free” feature allows the robot synchronize the takeout of parts as they’re being ejected, instead of waiting for the ejectors to fully advance before grabbing the part.

The Max series’ new control has up to 16 axes of control, versus 5 axes on the previous control. In addition to control of multiple additional movements on robot arm, this makes it possible to control downstream automation like an indexing rotary table from the robot’s control.

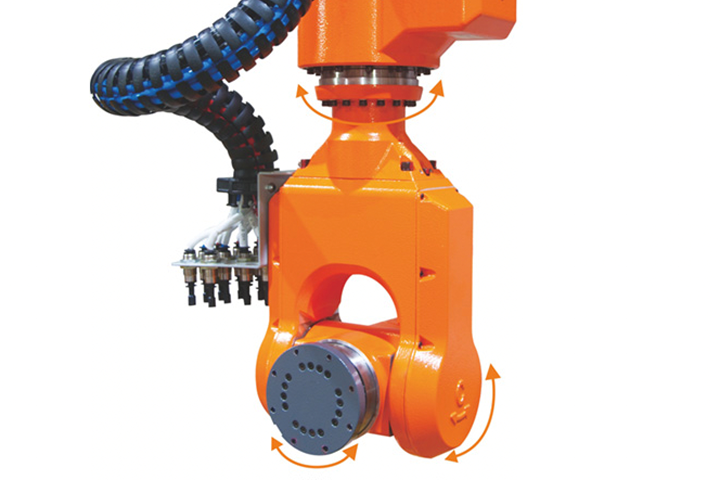

ARI says these additional axes augment the typical X, Y, Z movements with the ability to spin, grab, flip and reorient parts in exponentially more ways. The layout, programming and form-factor of the robot remains the same, which ARI says keeps it affordable and easier to operate compared to a floor-mounted 6-axis robot arm.

The new generation of robots are also equipped with higher performing ASDA A3 servodrives, upgraded from ASDA A2 drives, with the new motors delivering a 10 to 15% increase in speed.

Among the upgrades to Absolute Robot’s Max series of full-servo top-entry robots is the ability to spin, grab, flip and reorient parts.

Photo Credit: Absolute Robot

Related Content

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

PolyJohn Turns to Blow Molding, Doubles Its Productivity

Leading maker of portable sanitation products knew thermoforming, sheet extrusion, rotomolding and injection molding. Then it found the missing link to higher productivity and new markets: blow molding.