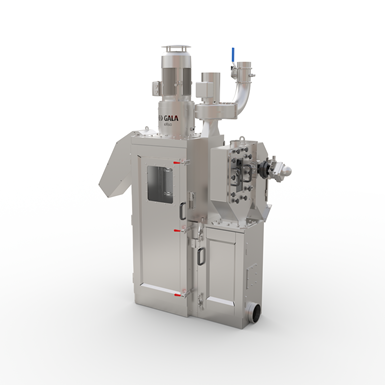

Centrifugal Dryer for Underwater Pelletizing

Units designed to improve reliability, reduce changeover time and improve product quality.

Maag’s new eXso centrifugal dryer reportedly has been designed to increase reliability, reduce changeover time and improve product quality. Its three-door housing, for example, allows greater access and visibility to the interior of the unit. This allows for faster and more effective cleaning and lowers the risk of cross-contamination.

eXso dryers are said to be ideal for compounders and recyclers who require a pellet drying step prior to packaging. Maag says the dryers have been tested and validated for rates up to 8200 kg/hr (18,077 lb/hr) and occupy 23% less floor space than previous designs.

Maag says the dryer was developed as a result of a focused effort to improve all aspects of its legacy dryers based on customer feedback. it maintaints it spent hundreds of hours validating the design and performance to ensure eXso exceeds the expectations of all customers, even those with demanding applications.

Related Content

-

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Engineering Resins Compounder Expands to Take on More Scrap

Polymer Resources responds to sustainability push by upgrading plant with grinding and shredding equipment to take on both postindustrial and postconsumer reclaim.