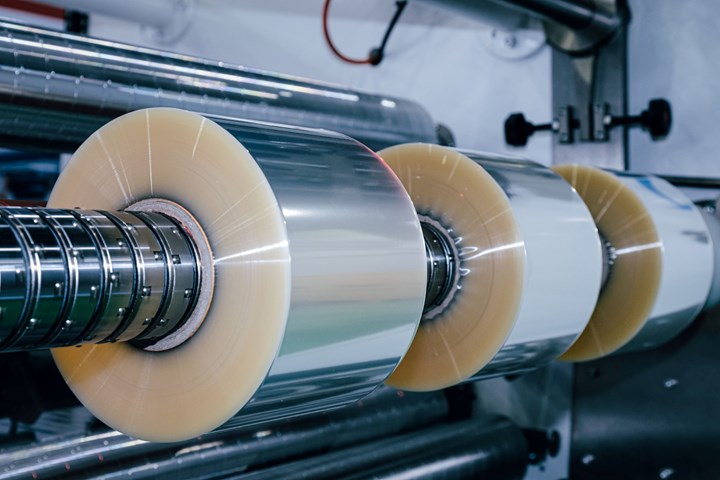

Clear Amorphous Nylon for Flexible Food Packaging

NPE 2024: NYCOA’s NY-Clear 6I/6T nylon targeted for packaging and precision molded applications.

A transparent amorphous high-temperature 6I/6T nylon copolymer has been launched for packaging and precision molded applications by Nylon Corp. of America (NYCOA). More specifically, the new NY-Clear 6I/6T series is targeted for use in flexible food packaging and coated beverage paperboard stock requiring high strength, stiffness and hydrolysis resistance. The NY-Clear portfolio consists of grades which are optimized for injection molding components with high dimensional stability and gloss as well as grades optimized for blown film and extrusion applications.

These nylon copolymer grades boast high clarity and strong permeation resistance with up to 30% higher resistance on oxygen, CO2 and water vapor transmission over competitive materials in the market. Such copolymers are known to offer higher temperature resistance, lower moisture absorption and better retention of properties compared to nylons 6 and 66. Moreover, NY-Clear grades can be used in higher temperature applications such as oven bags. Amorphous nylons are known for their excellent dimensional stability, high Tg, heat deflection temperature (HDT), low creep at elevated temperatures and good chemical resistance compared to many high-performance engineering plastics. NYCOA says significant cost benefits can be realized for amorphous nylons sourced from the company’s Manchester, New Hampshire, production facility, compared to imported resins.

Related Content

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.