Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

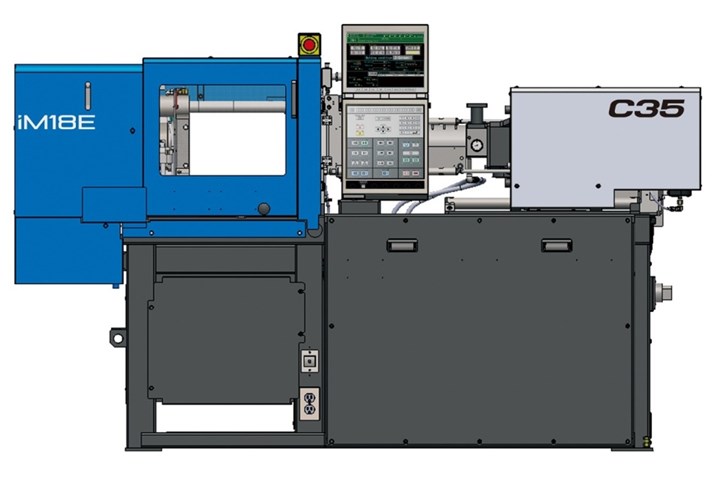

Sumitomo Heavy Industries Ltd. (SHI) of Japan launched the 20-ton iM18E compact hybrid injection molding machine with a footprint of just 88 by 30 in. on Jan. 31, 2023. Designed especially for molding connectors, precision gears and other electronic parts, the iM18E has a maximum injection speed of 600 mm/sec. A company spokesperson told Plastics Technology that at this time the machine will only be sold in Japan and other Asian markets.

SHI says the iM18E occupies approximately 21% less space than the company’s equivalent model SE18DUZ. Floor space required for the iM18E is greatly reduced thanks to a redesigned injection unit and a machine frame that allows peripheral equipment to be housed under the machine.

The iM18E’s features a hydraulic direct-pressure clamp, with an electric plasticizing unit featuring a low-inertia servomotor. Controlled by the ISCII direct-drive system, SHI says the iM18E reduces shot-to-shot weight variation to about one-third of that of an equivalent hydraulic machine. The hybrid design reportedly reduces power consumption by 50% in comparison with the equivalent hydraulic machines.

The 20-ton iM18E compact hybrid injection molding machine occupies approximately 21% less space than the company’s equivalent press.

Photo Credit: Sumitomo Heavy Industries Ltd.

Related Content

-

Plastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

-

High-Performance Nylons that Bridge Gap Between Nylons 6/66 and PPA

BASF’s new Ultramid T6000 and T7000 offer several performance and processing advantages.

-

High-Performance PPA for Next-Generation IGBT Semiconductors

BASF’s Ultramid Advanced N3U42 G6 is tailored to enhance robustness, long-term performance and reliability.