Compounding: Closed-Loop System for Coex Film Reclaim

New system permits reclaim of multi-layer production scrap at rates up to 100%.

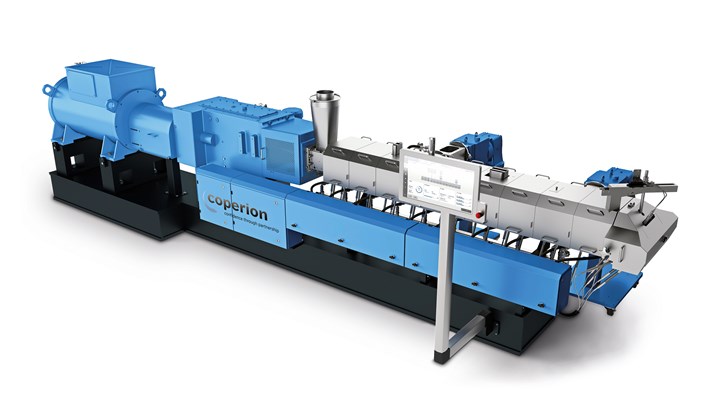

Coperion has developed a closed-loop system for recycling post-industrial multi-layer film, a recovery process that historically has been challenging and complicated. The recycling system consists of bulk material handling equipment, a Coperion K-Tron feeding system and Coperion’s ZSK Mc18 twin screw extruder.

In the Coperion setup, multi-layer production scrap would first be shredded, then fed into the ZSK extruder via pneumatic conveying and highly accurate feeding from Coperion K-Tron. In the co-rotating ZSK Mc18 twin screw extruder, material is homogenized and devolatilized. Coperion says the extruder is designed to “gently” and thoroughly mix the material even at very high throughput rates, generating consistently high product quality.

Following homogenization, the recycled material is added back into the production process at rates up to 100%.

Related Content

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

-

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.