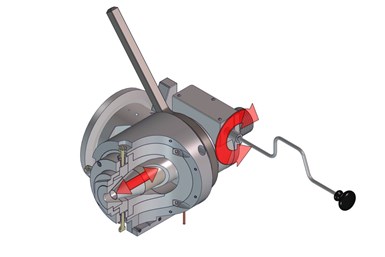

Crosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Guill Tool’s 500 Series crosshead is designed specifically for the flow characteristics and unique processing challenges of elastomeric compounds. One of the key features engineered by Guill on this new crosshead design is the mechanically assisted gum space (MAGS) adjustment system. This new method of gum space adjustment enables the operator to make an effortless adjustment from a single point using a common socket wrench. No more need to struggle with multiple nuts and bolts in order to adjust gum space, which leads to faster adjustments. The visual indicator on the core tube enables the operator to see how far the gum space has been moved, making those adjustments much more accurate and repeatable.

The hardware-free and patented cam lock design of the 500 Series means no time is wasted unbolting and resecuring fasteners for disassembly and reassembly. Only half of a rotation of the cam nut is required to loosen and automatically extract the deflector from the head body, which is another time saver. Also, with no undercuts on the deflector, there are no material hang-ups when extracting the deflector, enabling faster and easier cleaning and changeover.

The crosshead also features the latest center-stage concentricity adjustment system that significantly reduces pressure on the tooling, enabling easier and more precise concentricity adjustments without loosening the face bolts. Easy-Out inserts for the adjusting bolts also enable simple replacement of locked or damaged adjusting bolts, which further saves on repair and downtime.

Another innovative feature of this new rubber/silicone crosshead is a cast aluminum liquid-fed cooling sleeve that enables the user to switch out the cooling jacket in the event of a line obstruction, again reducing downtime compared to traditional integrated cooling systems.

The NEW 500 Series crosshead with MAGS gum space adjustment is a drop-in replacement on most existing NRM lines, however this crosshead design can also be adapted to fit any extruder design or line layout.

The addition of a newly designed flow inlet channel reduces the shear and heat that is generated as the materials are being processed. This leads to lower head pressures, enabling the material to move through the head in a much more balanced and even flow.

Related Content

-

Tight-Tolerance Molder Dips Toe in Extrusion Waters

Midwest Precision Molding brings extrusion capacity in-house to assist a customer that was having a sourcing issue with its existing overseas suppliers.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Making Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.