Direct Communication, Control Between Cobots and IMMs

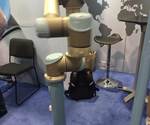

NPE2024: Universal Robot is showing how its Injection Molding Machine Interface (IMMI) module facilitates direct communication and control between its robots and molding machines.

Universal Robots’ Injection Molding Machine Interface (IMMI) Module enables direct communication and control between Universal Robots and injection molding machines. The modules can control mold movements, including ejectors, cores and open/close, as well as monitor rejects from the press. Safety devices between the press and robot can be integrated, and the module is compatible with standard communication protocols, including Euromap 67 and SPI AN 146.

A user interface is directly accessible in the cobot’s own teach pendant for easy integration, programming and control. NPE2024 will also feature cobot demonstrations by UR partner DesignPort. Visitors can see the cobots perform various tasks, including assembly of molded plastics parts to other plastics, as well as joining of molded plastics to nonplastic elements. There will also be demonstrations of cobot-powered pre- and post-mold operations, including insert loading and runner degating.

Universal Robots will display the integration of cobots with injection molding at NPE2024. Source: Universal Robots

Related Content

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.