Direct Gating of In-Mold Decorated Parts

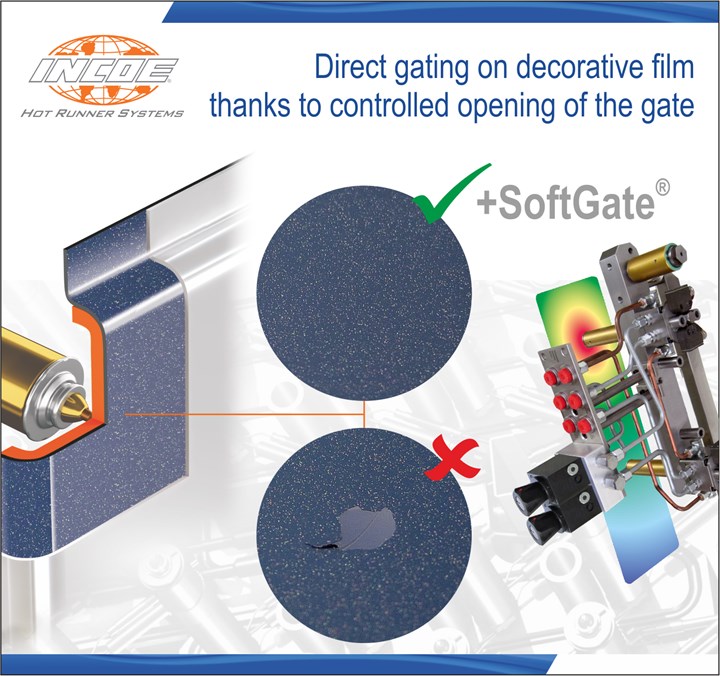

Incoe’s SoftGate Velocity VG pin control technology allows direct valve gating of parts with an over-molding film or fabric.

Share

In mold decorating (IMD) involving the over-molding of film or fabric and utilizing direct valve gating typically results in the “blast” of the plastic in the gate area damaging the film or wrinkling the fabric. To combat this, Incoe (Auburn Hills, Mich.) introduced its SoftGate Velocity VG pin control technology, which allows these types of applications to be direct gated without surface blemishes. Specifically, SoftGate allows the melt to stream over the decorative film without damaging it. This technology will be on display at the PTXPO (March 29-31; Donald E. Stephens Convention Center; Rosemont, Ill.)

The impact caused by melt flowing abruptly into the cavity after the valve gate nozzle has been opened conventionally can be seen in the image detail.

Photo Credit: Incoe

Related Content

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.