Edge Encapsulation Boosts PLA Coating Speed

Technologies increases throughput, reduces coat weight in the extrusion coating of biopolymers by encapsulating the edges of the coating with LDPE.

SAM North America LLC and Nordson Corp. have determined that extrusion processors can increase throughput and reduce coat weight coating with biopolymers such as PLA by encapsulating the edges of the coating with LDPE.

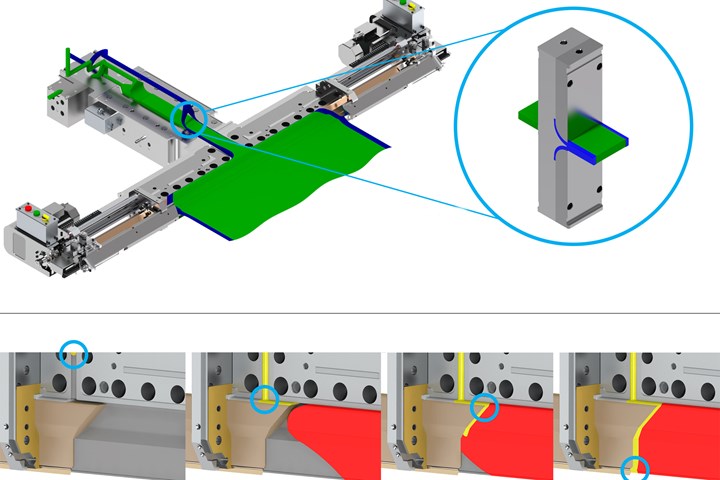

While conventional coextrusion yields two or more materials in horizontal layers, special encapsulating inserts developed by Nordson for its coextrusion feedblock make it possible to extrude additional material along either edge of this horizontal structure. Using this technique, SAM North America has found that encapsulating a PLA coextrusion with edges of LDPE makes it possible to offset deficiencies of PLA—in particular its low melt strength—that have limited its melt curtain stability, draw-down ratio, line speed, and coat weight.

While edge-encapsulation itself is not new technology, SAM says when utilized in this technology it has achieved line speeds in excess of 1200 ft/min with PLA when using LDPE edge encapsulation on a pilot line, as against less than 600 ft/min with PLA alone. SAM says it has run on a variety of substrates, among them paper, paperboard, and various films, including cellophane.

The high melt strength of LDPE has helped make this polymer by far the most widely used in extrusion coating. “For processors wishing to replace some portion of their LDPE usage with biopolymers, a main obstacle has been that their lower melt strength causes extreme neck-in and edge instability at desirable line speeds,” notes Sam Iuliano, chief technologist for Nordson’s EDI extrusion die and feedblock business. “By introducing a higher-melt strength material on each edge of the melt curtain, edge encapsulation minimizes the processing limitations posed by many biopolymers.”

Neck-in is the tendency of the polymer web to become narrower as tension is applied when it exits the die. The result is a build-up of material along the edges of the web, or “edge bead,” that must subsequently be trimmed away as scrap. To ensure that this edge bead consists of the lowest-cost polymer in the coextruded structure, Nordson has developed customizable feedblock inserts that introduce flow of the low-cost polymer only at the edges of the structure. The combined materials are then distributed to the final target width in the flow channel or manifold of the die.

While the encapsulation inserts can be readily retrofitted into existing EDI feedblocks, Nordson offers new EDI dies equipped with the EPC deckle system, which can be adjusted to reduce edge-bead formation, and a melt flow system in which the edge encapsulation polymer is introduced in the die rather than in the feedblock. The port for introducing the encapsulation polymer moves in concert with the deckle mechanism.

Andy Christie, managing director of SAM North America, will discuss this topic at the Extrusion 2021 Conference, Sept. 21–23 at the Donald E. Stephens Convention Center, Rosemont, IL.

Related Content

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

-

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.