Reciprocating Head Enables Profile-Shape Changes 'On the Fly'

NPE2024: Device eliminates the need to change tools to accommodate different profile shapes and eliminates assembly of the finished profile.

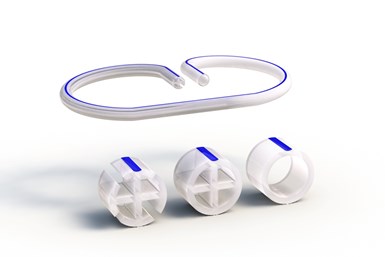

On the new reciprocating head developed by Guill Tool, the typical tip and die assembly is replaced with a linear reciprocating assembly that changes the tube’s profile on the fly within a given length. This process is repeated throughout a single extrusion run without interruptions. As a result, only one extrusion run is needed to produce a finished product, as opposed to multiple runs requiring tooling changes and manual assembly operation to connect different tubing shapes. Guill’s new reciprocating head also eliminates in-process inventory.

Source: Guill

This means there is no need for storage of various tubing shapes and connectors needed for assembly, fulfillment of orders and replenishment of finished goods.

Moreover, the reciprocating head eliminates a connecting piece, enables JIT production and products made-to-order, and reduces total run time from receiving the order to shipping, according to Guill.

Related Content

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

-

Why Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

-

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.