Flexible Twin for Small-Lot Compounding, High-Output Extruder

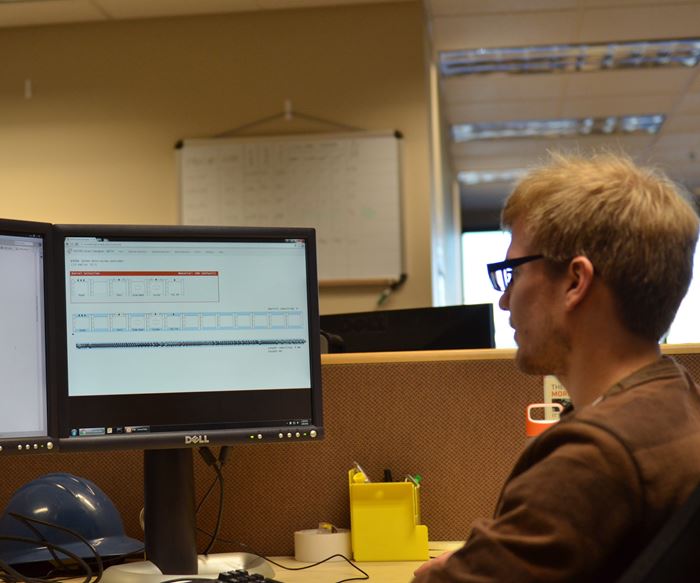

ENTEK displaying two new twin-screw extruders in an interactive display that also features its screw layout program.

ENTEK is displaying two machines in its booth: its new QC3 33-mm co-rotating twin-screw extruder, which was introduced in 2017 and is being shown publicly for the first time; and its high-output co-rotating 73-mm twin-screw extruder. ENTEK is also featuring two interactive work stations at its booth showing the company’s unique screw-layout software program.

The QC3 33-mm twin is a new size designed for small-size lots of compounds and includes all of the company’s latest QC3 (Quick-Change, Quick-Clean, and Quality Control) features.

The new QC3 33-mm joins ENTEK’s other QC3 models, which include its 27-, 43-, and 53-mm co-rotating twins. The company also manufactures 73-, 103-, and 133-mm models.

New mechanical design features being incorporated into the extruder include a patented self-aligning screw-gearbox couplings to facilitate fast and fool-proof installation of screws; lock and key feature on splined shafts to prevent screw timing errors; conveniently located gauges for quick monitoring of lube and cooling system running conditions; a quick change strand die; and enhanced controls.

ENTEK’s is also featuring its 73-mm twin for high-output custom compounding. It’s available with a 600-hp motor and screw speeds up to 900 rpm.

ENTEK’s unique screw design program is also featured at its booth. The company has two interactive work stations at its booth where visitors are encouraged to see how easy it is to quickly design screw and barrel layouts for their specific applications.

Related Content

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

-

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

-

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.