Flexible Twins for Profiles

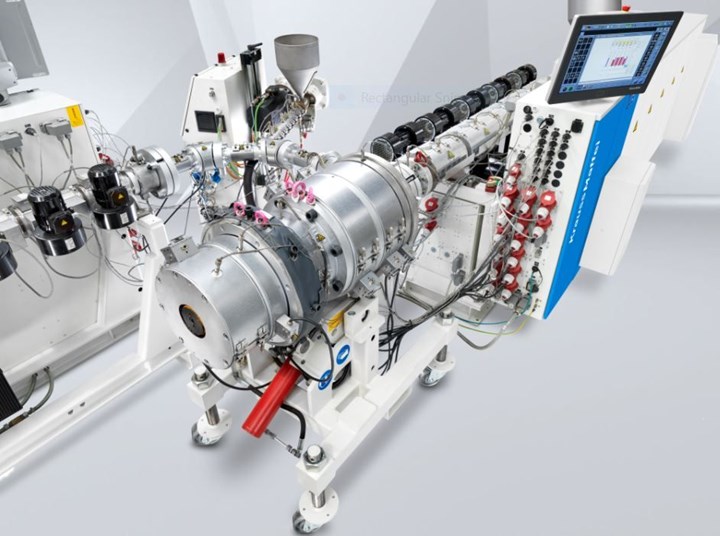

Profile extrusion lines from KraussMaffei Berstorff are provided from single machines to complete production lines.

Profile extrusion lines from KraussMaffei Berstorff are provided from single machines to complete production lines. The machine builder’s flexible product portfolio for high-performance profile extrusion ranges from 32D conical and parallel twin-screw extruders to coextruders for integrated extrusion systems in piggyback or tandem configurations.

Profile extrusion applications include:

- PVC coex foam boards;

- Main and auxiliary window profiles;

- Coextruded window profiles;

- Expanded profiles;

- Door systems;

- Roller shutter systems;

- Window sills;

- Gutters;

- Cable conduits;

- Technical profiles;

- WPC/NFC profiles; and

- Siding solutions.

KraussMaffei Berstorff will be participating at the Extrusion 2021 Conference, September 21-23, Rosemont, Ill.

Related Content

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

-

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

-

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.