Hot Runner Advances for Smaller Shot Weights and Thinner Walls

Oerlikon HRSflow will launch a range of hot runners tailored to small shot weights and the new Xp nozzle series for use in thin wall injection molding at K 2022.

At K 2022, Oerlikon HRSflow will highlight sustainability enabling hot runner advances in its own booth and those of several partner companies. In addition, applications of Oerlikon FLEXflow’s valve-gate hot runner technology and other advanced hot runner solutions specifically designed for post-consumer resin (PCR) materials and biopolymers will be displayed at several partner companies. The company will also highlight a joint development process utilizing simulation technology undertaken with Engel and Borealis.

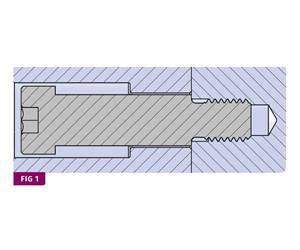

Oerlikon HRSflow has expanded its portfolio to support small shot weights, which require tight nozzle pitches, now offering complete systems for this segment. The portfolio includes nozzles with small dimensions in thermal and valve gates, as well as the associated manifolds and actuation mechanisms.

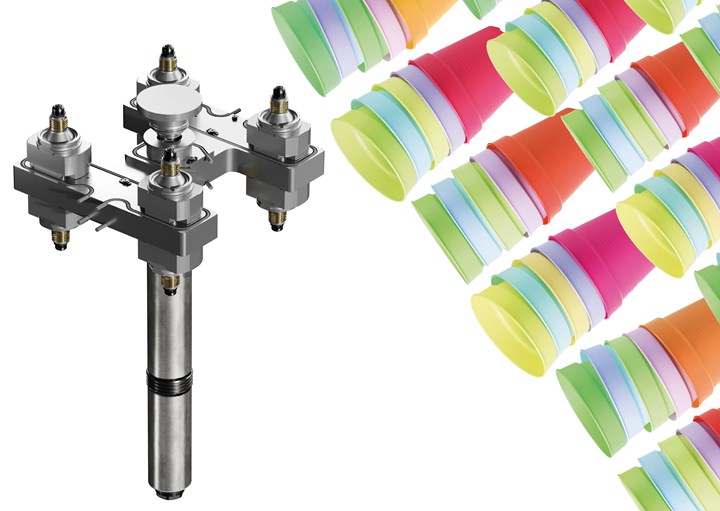

For multi-cavity applications, a multi-valve plate (MVP) offers synchronized control of the injection channel across all cavities for high part-to-part weight consistency. Oerlikon HRSflow says the systems also offers fast color changes and easy restart, further reducing waste and increasing efficiency.

The company says this new low-shot-weight line covers markets like medical, thinwall packaging, beverages, caps produced in multi-cavity molds, as well as beauty and personal care and technical applications. Further it says the latest version can process biopolymers and PCR compounds. A version with a specially coated nozzle tip is available for processing highly corrosive polymers including flame retardant compounds.

For the most demanding applications, Oerlikon HRSflow uses its in-house additive manufacturing to produce cooling circuits for all market segments. Thanks to the joint experience with sister brand Oerlikon Balzers, Oerlikon HRSflow can offers surface protection for all molded parts.

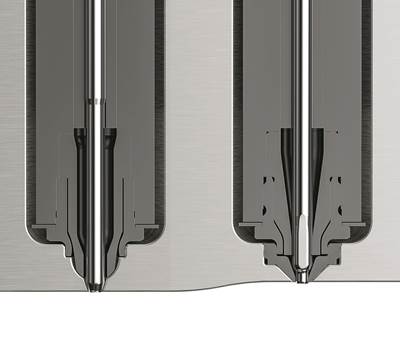

New Valve-Gate Nozzles

The new Xp series of valve gate nozzles is designed to withstand filling pressures up to 2200 bar (approx. 32,000 psi) and enable fast injection, short cycles and stable processes with high part weight consistency. In addition, a patent-pending solution for stack systems in thin-wall injection molding has been developed. Oerlikon HRSflow says assembly is simplified by a plug-and-play installation. This hot runner system, which enables the use of smaller injection molding machines, fits a maximum plate thickness of 240 mm (approx. 9.5 in). The company says this allows for perfectly symmetrical systems with up to 8+8 drops to be supplied, and a minimum pitch between cavities of 65 mm (2.5 in) and between nozzle and inlet of 120 mm (4.75 in).

To support the trend in automotive interiors where in-mold decorated (IMD) interactive panels controlled by touch sensors are featured, the company offers its FLEXflow hot runner technology, with servodriven needle positioning.

Oerlikon HRSflow has recently updated the FLEXflow hot runner systems controller, including the ability to integrate different nozzle types and store parameters for different molds. There is also the possibility for individual control of servomotors for nozzle needle positioning and for monitoring process stability. In addition, specific user accounts for individual access authorizations can now be set up and managed. Thanks to the web connection, access to the control unit is possible regardless of location.

New Coating

In cooperation with sister company Oerlikon Balzers, the company is offering what it calls an innovative coating protection for molded part surfaces. A current application includes BMW’s iXe all-electric SUV, which applies Oerlikon Balzers embedded PVD for design parts, or ePD. This environmentally friendly coating process can be used wherever high-quality, metallic-looking surfaces on plastic parts with intelligent functionality are required.

Partner Collaborations

Oerlikon HRSflow systems can be experienced live on the exhibition stands of Engel (door panel and smart rear panel); Tederic (2K high=gloss B pillar); Arburg (multi-component tool box made of PC+ABS and reclaimed PET resin: Recopound), Haitian (fruit box made of PE plus Tetra Pak recycled shredded flakes), Wittmann-Battenfeld (three-component coffee cup), Billion (garden tool), and Netstal (recycled PP thin-wall cup).

During the show, Oerlikon HRSflow, Engel and Borealis will report on a jointly realized project which, using a family mold with three different cavities, shows how close simulation and reality can be when partners fully collaborate. Instead a more typical sequential approach, the participants took on development steps simultaneously, providing all relevant data of the injection molding machine, valve gate hot runner system and the processed material for a quality flow simulation. Oerlikon HRSflow says that compared to conventional sequential cooperation, the time between initial mold sampling and tool commissioning was significantly reduced.

Oerlikon HRSflow will showcase hot runner technologies for smaller tighter-pitch applications as well as thin-wall moldings.

Photo Credit: Oerlikon HRSflow

Related Content

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreRead Next

Oerlikon Acquires INGlass and its HRSflow Hot Runner Business

The Swiss maker of flow control components, including gear metering pumps, has acquired the Italian headquartered mold maker and its hot runner unit.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More