Hot Runners: Control for Hydraulic Needle Drives; Wear-Resistant Design for Abrasive Resins; and Specialized Film Insert Molding System

HRSflow has introduced a trio of developments, offering precision needle control in hydraulic systems, wear-resistant hot runners for filled resins, and a line targeting film insert molding (FIM), for the back molding capacitive films, for example.

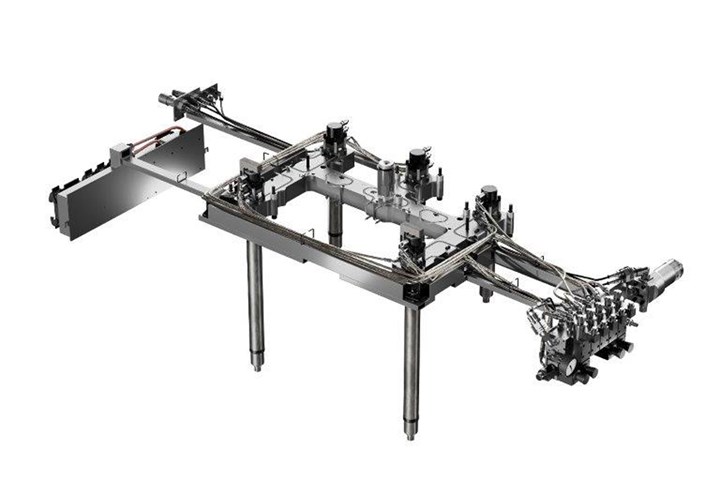

Italian hot runner supplier HRSflow (U.S. headquarters Byron Center, Mich.) says its new HyFlow technology allows precise control of hydraulic needle drives and can be installed on a full system or select actuators, for a “hybrid” system.

HyFlow specifically targets cascade injection molding for hydraulically actuated hot runner systems, so that the opening and closing speeds, as well as the positioning of each individual pin, can be precisely adjusted via the oil flow rate.

An HRSflow spokesperson told Plastics Technology that the HyFlow can be retrofitted to existing hydraulic systems but the pockets in the tool would have to be modified, as the new cylinders are larger than the standard ones. If a customer is considering an upgrade, HRSflow notes that it has “ready” versions were a direct upgrade is possible since the pockets have been designed from the beginning to accommodate the cylinders.

HyFlow technology allows precise control of hydraulic needle drives.

System Targets Filled Resins

HRSflow also launched the Hyper-GF series for processing abrasive thermoplastics. Targeting glass-fiber-reinforced materials, the Hyper-GF series extends the service of the hot runner according to HRSflow, even in high-volume processes. The longer service life derives from the use of special steels and an optimized flow channel design, according to the company.

Back Molding Films

In a current pilot project with a customer, HRSflow shows how its FLEXflow Evo servodriven valve-gate systems can be used when back molding sensitive films. Partnering with film manufacturer Kurz, a film featuring functional capacitive elements for touch operation and decorative elements was back-injected with a clear polycarbonate (PC) in a single step, enabling backlighting in the area of the operating elements. HRSflow says the servodriven FLEXflow Evo technology prevented the thin functional and decorative elements from showing internal stress that would be seen in conventional cascade injection molding. This was due to the evenly distributed, low-pressure spreading of the melt flow front. Damage to the film was also avoided.

Related Content

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.