Injection Molding: New Robots & Customer Portal for Monitoring & Remote Assistance

Campetella’s open house showcases enhancements in performance and service.

At an open house at its Italian headquarters this past fall, Campetella Robotic Center (CRC) discussed several new developments in robotic hardware and a new customer web portal for robot condition monitoring and remote maintenance. “We have used the past few months to bring new robot developments to series production readiness,” explained general manager Elia Campetella. “The focus is on footprint reduction, precision, longevity and speed, with standardized solution concepts in modular design.” Given the decline in the automotive sector during the COVID-19 pandemic, CRC has focused largely on industrial and food packaging and medical markets. In fact, says sales manager Marco Marconi, “Our order books are full until April.”

At the Campetella open house, four-cavity PP yogurt cups with IML were molded in just 1.9 sec.

Campetella is represented here by Hunter Automation & Robotics, Sterling, Mass. (campetella.com). Among CRC’s newest developments:

• In development is a customer portal that will allow users to remotely monitor the operating status and health of all the installed automation systems and easily access documentation and tutorials for maintenance, assembly and disassembly. It will also allow for remote assistance from CRC technicians with the aid of augmented reality vision systems.

• The new Double Concept is a two-armed side-entry linear robot for high-speed packaging applications in stack molds. An evolution of CRC’s Concept X Series, it has a guaranteed cycle time of 3.9 sec for applications like disposable cutlery and coffee cups. It can handle up to 2 × 72 cavities.

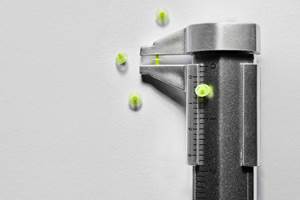

• The company’s best-selling CO1 X-Series top-entry robot was recently upgraded in speed and reliability and now also has shorter lead times. Payload capacity is up to 10 kg and cycle time is 5.5 sec, suiting it to injection presses up to 200 tons.

• CRC also has a new in-house 3D printing facility that produces label carriers (“dummies”) for label inserting in IML, as well as cable-carrier links and other plastic components.

Two demonstrations at the open house illustrated CRC’s core capabilities. Both demos utilized special enhanced-performance packaging versions of Arburg hybrid Allrounder Hidrive injection machines. In one demo, four PP yogurt cups (200-ml) were molded with IML on a packaging version of a hybrid Allrounder 570H (180 metric tons) in 1.9 sec. A CRC X-Series Mini-Modula side-entry robot inserted the labels and removed the cups, weighing 4 g each. A tilting wrist axis allowed the cups to be stacked upside down with their openings on a conveyor belt. An upgraded version of the X-Series CO1 top-entry servo robot moved the stacks of cups from the conveyor to a box. Boxes were removed by an Omron AMR (autonomous mobile robot).

An Omron AMR (autonomous mobile robot) removed boxes of finished products from conveyor to storage.

The second demo involved four PP tubs for cheese spread (200 ml, 7.55 g) with IML, molded on a packaging version of a hybrid Allrounder 630 H (230 m.t.) with Arburg’s new look and clamp design, as well as the new Gestica controller. In a 3.0 sec cycle, An X-Series Modula side-entry robot inserted five-sided labels and removed the parts. Four electronic cameras monitored quality. Again, the tilt wrist placed the cups upside down on the conveyor for hygienic purposes. An X-Series Spin3 SCARA robot moved the stacks into boxes, which were carried away by an Omron AMR.

Related Content

In-Mold Labeling Adjustment Head

Beck Automation says the new adjustment head targets production of small medical consumables packaging.

Read MoreIn-Mold Labeling Applied to Medical

In collaboration with multiple partners, Arburg will showcase IML for centrifuge tubes at Fakuma 2023, eliminating printing or other downstream steps.

Read MoreSlimmer All-Electric Press Debuts

NPE2024: A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreRead Next

NPE2018: Robots & Automation Tackle Increasing Complexity

Exhibitors highlighted brute strength, complex automation cells, wireless networking, new controls features, and “collaborative” applications. Automated one-minute mold change was another attraction.

Read MoreBigger, Faster, Lower-Cost Robots at K 2019

Three, four, five and six axes; high speed and high payload capacities; low-cost models; and collaborative robots made news at K. There were also QMC systems and AGVs.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More