Injection Molding: Store, Manage & Analyze Mold Simulation Data in the Cloud

Moldex3D iSLM helps manage, share and easily analyze large volumes of mold simulation data.

For companies that must store and manage large amounts of CAE mold simulation results, CoreTech System Co. of Taiwan offers a cloud-based “big data” solution that also offers a number of ways of analyzing such data libraries. Called iSLM, this new web-based cloud service for centralized simulation data management is part of the Moldex3D 2020 release. Moldex3D iSLM is said to streamline CAE data management and to allow for easy exchange of information among development team members—part designer, CAE engineer, mold designer and molder. The storage structure is based on mold number as the key identifier. iSLM allows user to access and correlate many types of data related to that mold that are often isolated in different storage systems:

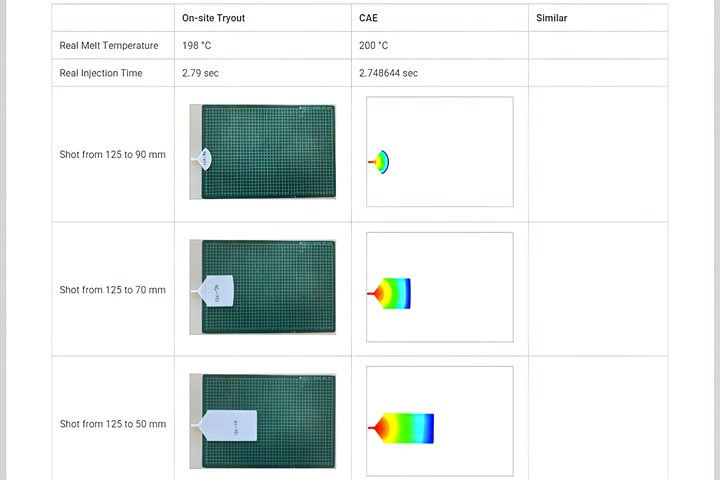

Moldex3D iSLM can store simulation and mold tryout results and then automatically prepare a report comparing simulated flow-front advancement with photos of short shots.

• Users can upload Moldex3D projects to iSLM and utilize the cloud platform as the main backup system. It can extract and preview project data automatically, saving the time for file transfer and email communications. Analysis capabilities include preparing reports comparing simulation results according to data on mesh, material and processing parameters. A 3D viewer is available to all team members to inspect simulation results.

• Users can upload any mold-related documents to the system, including DFM (Design for Manufacturing) reports. iSLM allows users to customize DFM reports so that DFM data will be recorded in consistent form.

• iSLM can provide the molding parameters used in a simulation for live mold tryout. Tryout results, including photos and notations of product defects, can be uploaded to the system, which then automatically generates tryout reports. Product quality inspection records can also be uploaded. Users can use the system to compare actual mold tryout results with the virtual simulation—for example, comparing flow-front advancement in the simulation to photos of actual short shots.

• Knowledge-management capabilities also include comparisons of historical designs, searchable by means of filters relating to industry, customer, application, etc.

Related Content

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.