Injection Molding: Upper Range of High-Speed Packaging Presses Extended

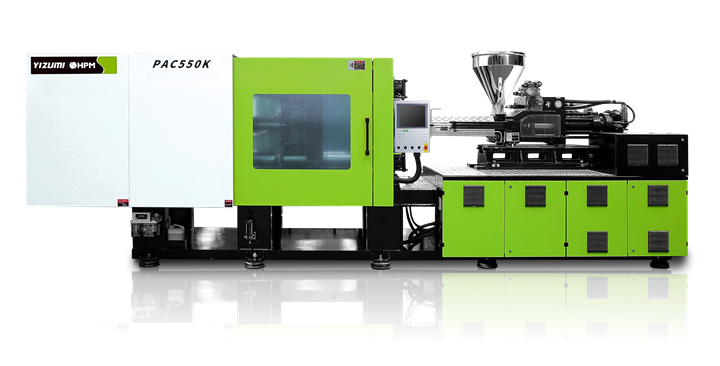

Yizumi-HPM has expanded its PAC-K series of injection molding machines, adding a fourth model with 610 tons of clamping force.

Yizumi-HPM Corp. has added the PAC-K-610 model to its PAC-K series, which now includes four machines—275, 385, 500 and 610 tons—with shot sizes from 5 to 74 oz. Utilizing a servo-hydraulic pump system for energy efficiency, the PAC-K series can achieve injection speeds up to 23 in./sec (585 mm/sec).

The toggle clamp features a negative-angle toggle and large beveled structure to create rigid platens that reportedly better transfer clamping force from rear platen to the center of the moving platen, minimizing deflection.

The clamp’s linear bearing guides help reduce friction, which lowers energy consumption and improves operating speeds. A high-response servo-proportional valve is used for speed and position control.

PAC-K series injection units have a compact, in-line injection cylinder that reportedly provides low inertia and rapid acceleration with a high level of accuracy. Infrared heater bands are standard—Yizumi-HPM says they can reduce heat losses by 30% to 50% over conventional ceramic heater bands.

Yizumi HPM has added a fourth machine to its PAC-K series of high-speed presses for packaging: the PAC-K-610.

Related Content

-

Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

-

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.