Long-Stroke Shuttle Blow Molders for Challenging Applications

Wilmington Machinery is offering to build special, customized machines for difficult applications up to 1.5 gal.

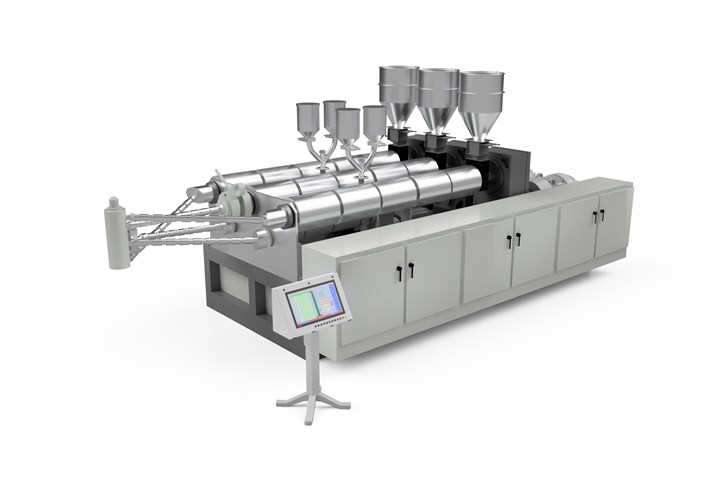

In response to customer requests, Wilmington Machinery is offering to build customized long-stroke shuttle blow molding machinery for applications not well suited by other such machines on the market. According to sales manager Jim Boos, such applications could include larger containers with heavier walls and unusual geometries. Anticipated applications would range from 6 oz 1.5 gal.

Coextrusion of up to six layers is available on the long-stroke machines and is also newly available as stand-alone coex packages.

These machines, like all Wilmington blow molders, are now supplied with new and more sophisticated control systems that offer remote troubleshooting, SPC charting, trend analysis, graphing and integrated auxiliary control on a large flat-panel display.

Also available on the long-stroke machines is coextrusion capability in up to six layers for single or dual parisons and all container sizes. Coextrusion is now for the first time available from Wilmington not only as part of machine systems, but also as stand-alone packages.

Related Content

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

-

Plastics Technology Year in Review: Your Favorite Reads of 2024

A year-end review of the top stories showcasing industry trends, advancements and expert insights. Revisit the articles that captured the attention of the plastics community.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.