Markforged Introduces New Simulation Package for its Additive Manufacturing Software

Launched at Formnext, Simulation seeks to replace the slow and costly design/print/break testing cycles with virtual testing.

Share

At Formnext in Frankfurt, Germany, Markforged released new simulation features for its additive manufacturing software. Simulation is available as a free trial until April 2023, and the company expects to make the feature accessible through a paid subscription thereafter.

Markforged says virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to help lower cost and speed production. The company also notes that more fully incorporating 3D printing into tooling and end-use applications requires confidence in finished part strength. Simulation seeks to replace the current design/print/break testing cycle norm with virtual testing.

As an example, Markforged points to Larsen Motorsports, which builds jet engine drag racing vehicles. These feature stock aluminum steering wheels that are designed for much larger hands than those of rookie House of Kolor sponsored dragster driver, Josette Roach. Larsen Motorsports used the new simulation feature to design and print a continuous carbon fiber reinforced Onyx steering wheel to replace aluminum and fit Roach’s hands.

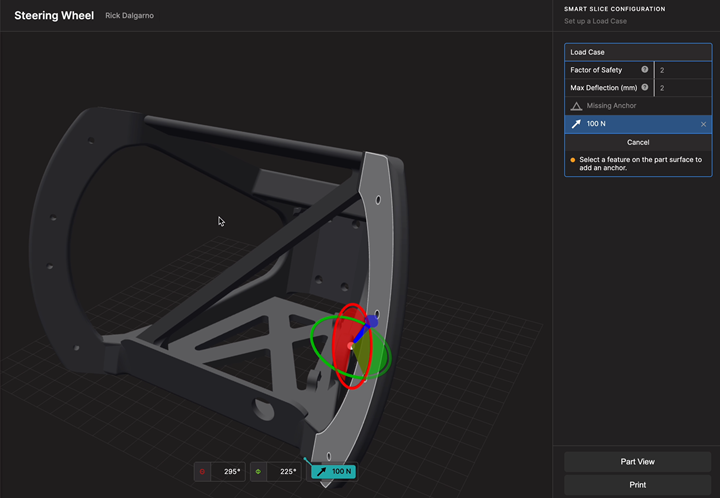

Markforged said its simulation program is designed for additive manufacturing and works within the familiar Eiger software slice and print workflow, so that any user can validate part strength and stiffness through virtual testing by identifying anchor and load surfaces and then entering values for loads, factor of safety and maximum deflection. They can then optimize parts by automatically determining print settings for floors, walls, infill and fiber reinforcement. Cloud-based Simulation is available worldwide as a free trial for anyone with a Markforged Eiger account.

Markforged Simulation can validate printed part strength and stiffness through virtual testing.

Photo Credit: Markforged

Related Content

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

-

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.