Materials: Novel TPU for Pneumatic Hoses and New Applications

BASF’s Elastollan 1598 is said to be the first ether-based TPU with the mechanical properties of ester-based TPU.

What reportedly is the first ether-based TPU that combines the highly effective hydrolysis and microbial resistance of ether TPU with the excellent mechanical properties of ester TPU has been introduced byBASF Polyurethanes & Plastics, Wyandotte, Mich.

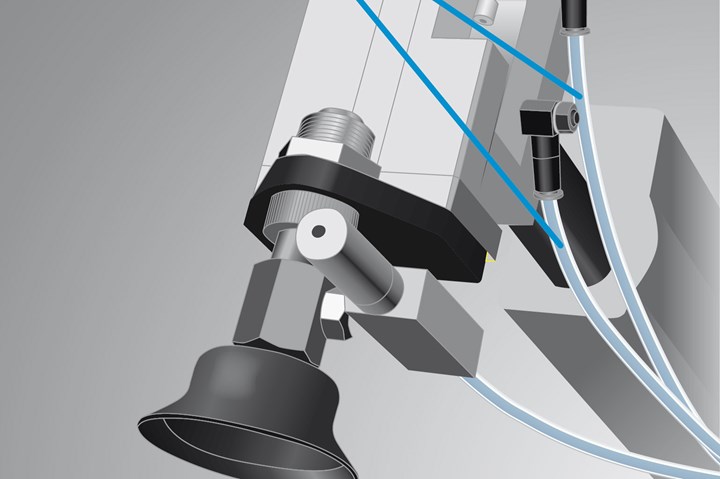

Elastollan 1598 A 10 FC, with food contact approval, is an aromatic TPU developed specifically to meet BASF’s customer requirements for pneumatic hose applications. Explains segment manager for extrusion TPU Mark Ottens, “With Elastollan 1598 A 10 FC, our customers can benefit from the advantages of two TPU worlds in one product. This expands the area of application within the target application of pneumatic hoses and the development of new fields of application. Due to the better burst pressure behavior in relation to temperature, the Elastollan 1598 A 10 FC can be used to achieve a higher operating temperature of pneumatic hoses compared to conventional ether TPUs.”

The main advantages of this novel TPU are said to be its outstanding product performance, especially at higher operating temperatures, characterized by significantly reduced creep behavior, increased bursting pressure and the bursting behavior itself. For BASF customers, this means a longer product life as well as an expansion of the field of application, for example, a higher requirement classification. In addition, Elastollan 1598 A 10 FC’s characteristics include outstanding crystallization behavior and robust dimensional stability, which results in excellent processability in extrusion. The excellent performance of this TPU reportedly widens the range of new industrial applications. For example, the reduced creep behavior combined with very good wear behavior makes this product ideal for the conveyor and belt sector. Here, a lower creep tendency leads to less slippage and, therefore, improves the conveyor belt’s operating life. In addition, Elastollan1598 A 10 FC is available in all colors and is classified for fire safety, according to UL94 HB.

Related Content

-

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

-

Baxter to Scale Up PVC Intravenous Bag Recycling Program

Successful pilot program with Northwestern Medicine will expand to additional units and health systems.

-

Custom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

Currier Plastics had a major stake in small hotel amenity bottles until state legislators banned them. Here’s how Currier adapted to that challenge.