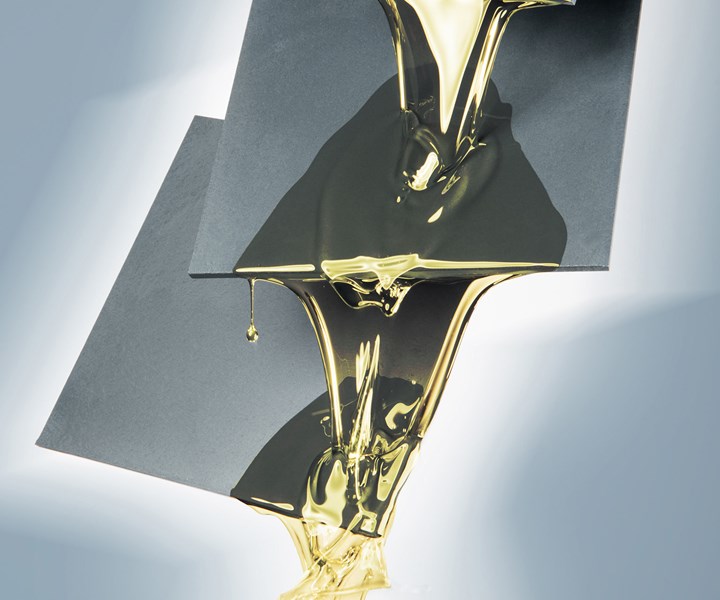

Materials: PES for Automotive Parts in Contact with Hot Oil

BASF’s Ultrason E0510 C2TR said to offer optimized sliding friction properties.

A new engineering plastic that is particularly suited for automotive parts that come into contact with hot oil has been launched by BASF Corp., Florham Park, N.J. New Ultrason E0519 C2TR polyethersulfone (PESU) reortedly has been shown to have very good tribological properties, high oil resistance and excellent dimensional stability over a broad temperature range. The injection-molding grade with 10% carbon fiber reinforcement can be used within a temperature range of -30 to +180 C (-22 to 356 F). It is said to be easy to process because of its low viscosity and very good flow properties.

Ultrason E0510 C2TR enables manufacture of various car parts that come into contact with oil: oil pumps, oil control pistons, pressure valves and high-speed components in automatic or manual gearboxes. Due to its good flow properties, parts with wall thicknesses of less than one millimeter can be injection molded. The low coefficient of thermal expansion of 10.4 [10-6/°K] ensures parts that are dimensionally stable and that can withstand rapid temperature changes. Tests according to ASTM G137 have shown that the sliding friction performance outperforms other tribologically optimized high-performance thermoplastics. Even at high wear rates, test components show only low wear with virtually unchanged mechanical stability and chemical resistance.

The new material combines its tailor-made features with the proven properties of Ultrason: extraordinary chemical resistance, inherent flame retardance, high rigidity and strength combined with outstanding hydrolysis resistance.

Related Content

-

PEEK for Monolayer E-Motor Magnet Wire Insulation

Solvay’s KetaSpire KT-857 PEEK extrusion compound eliminates adhesion and sustainability constraints of conventional PEEK or enamel insulation processes.

-

Molder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

-

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.