Materials: Purge and Shut-Down Masterbatches for Polyolefins

Ampacet’s new additions to its line of purge and shut-down concentrates are aimed at maintaining product quality and cutting costs,

Two purge and a shut-down masterbatches for polyolefins newly launched by Ampacet Corp., Tarrytown, N.Y., are said to help processors maintain product quality and reduce maintenance costs. Products 100400 Purge PE, 103828 NaturBlend TM Universal Purge, and 100401 Antioxidant PE Compound are said to quickly clean-down between resins or colors and minimize waste. According to strategic business manager Joe Serbaroli, Ampacet was the first masterbatch producer to offer these type of “housekeeping” products and the company continues to advance this product line, including the devevelopment of universal carriers that accommodate non-olefinc resins.

Colorants and degraded or incompatible resins can linger in extruders and process equipment, causing prolonged contamination of new product jobs. Both of Ampacet’s purge masterbatches, 100400 Purge PE masterbatch and 103828 NaturBlend Universal Purge, reportedly gently clean-out unwanted materials from equipment to accelerate job changes and colorant removal. 100401 Antioxidant PE compound may be used to charge the extruder prior to extended downtime, thereby reducing the likelihood of polymer degradation while idle and during subsequent start-up.

100400 Purge PE MB is said to be ideal for general purpose polyolefin applications. Used as a transition purge when making color or resin changes, it contains a mildly abrasive inorganic material, combined with other additives that provide a synergistic cleaning effect for maximum residue removal. Suggested use is 25% - 50%, depending on the amount of build-up.

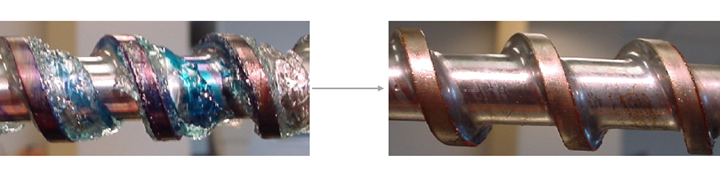

Thermally stable for high-temperature applications, 103828 NaturBlend Universal Purge MB is characterized as a highly-efficient purge masterbatch designed for blown and cast film extrusion, injection and blow molding and profile extrusion processes. It removes oxidized material from screws and barrels, cleaning the extrusion system for subsquent polymer runs and is specifically designed to purge mixes of incompatible materials, such as polyethylene and nylon. Suggested use is 25% - 50%, depending on the amount of build-up.

100401 Antioxidant compound is designed to reduce the oxidation of polyolefins remaining in the extruder during shutdown, start-ups and planned downtime such as line maintenance. Ampacet’s 100401 Antioxidant PE compound inhibits crosslinking, prevents oxidation, minimizes gel formation and the formation of carbon specks that can delay output of quality products on restarting production. Ampacet suggest using 100401 at 100% to charge the extruder prior to shutdown.

Related Content

-

Fundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

-

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

-

Polyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.