New Control Platform, Plus Lines for Sheet, Tubing

Navigator control system now extends to all of the company's brands, including Graham Engineering, Welex, and American Kuhne.

Graham Engineering Corp. is displaying extrusions systems for sheet, medical tubing, wire and cable, and other applications, each equipped with a proprietary Navigator control system for live demonstration of its accuracy and ease of use.

The extrusion displays include:

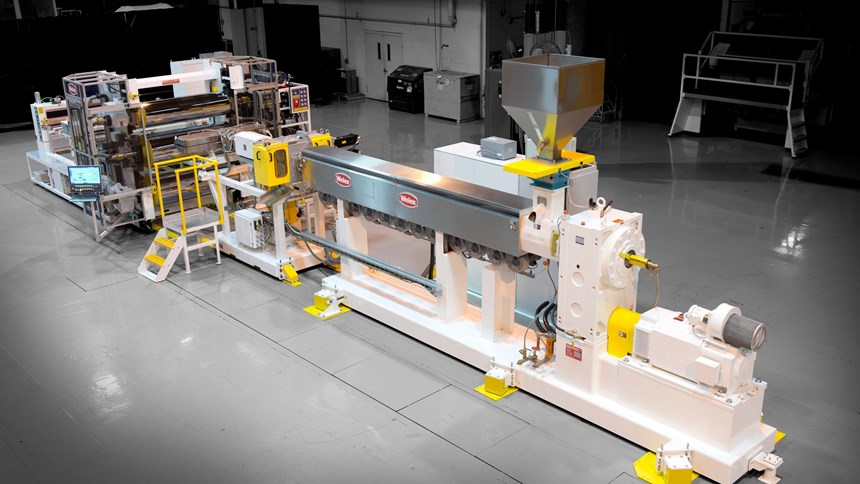

● A Welex brand Evolution sheet extrusion system—a complete production line for use in sheeting, winding, and in-line thermoforming applications equipped with XSL Navigator control. While the equipment on display is for thin-gauge PP, the Evolution system can be customized for widths from 36 to 90 in. (90 to 230 cm), gauges from 0.008 to 0.125 in. (0.2 to 3.2 mm), and throughputs up to 10,000 lb/hr (4535 kg/hr.). Monolayer or co-extrusion systems are available, with up to nine extruders. In addition to a customized roll stand, the Evolution system can also be equipped with screen changers, melt pumps, mixers, feedblocks, and dies. Additional features of the line on display include a proprietary roll-skewing mechanism for thin-gauge applications while maintaining quick roll change and electric gap adjustment under full hydraulic load without interrupting production.

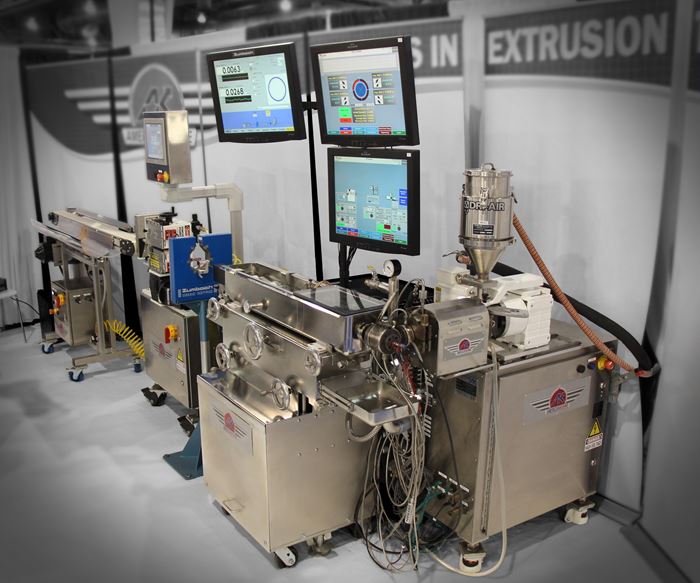

Originally developed for Graham Engineering extrusion blow molding systems and then adapted for Welex sheet extrusion lines, Navigator controls are now available for American Kuhne extrusion systems such as those for medical tubing, profiles, and wire and cable. There are three levels of functionality: XC100 for stand-alone extruders, XC200 for one or more extruders in simultaneous operation, and XC300 for integrated production lines with the extruder and components such as a puller, water bath, or winder. All three controls are shown installed on American Kuhne extruders.

● A 2.5 in. (63.5 mm) American Kuhne Ultra extruder equipped with XC100 Navigator control and a 3.5 in. (99 mm) extruder with XC200 Navigator control. Building on the proven performance of the Ultra family of extruders, Graham has made improvements designed to make maintenance simple and accessible. Serviceability features include newly designed barrel covers that allow for quick and easy access to barrel heaters and thermocouples and an automotive style wiring harness with quick-change plugs for routing wiring and thermocouples between the electrical cabinet to the barrel heater/cooling zones.

● American Kuhne tri-layer medical tubing line, consisting of modular micro extruders and XC300 Navigator with integrated the TwinCAT Scope View high-speed data-acquisition system.

● American Kuhne AKcent co-extruder. This versatile customized system is available in fixed horizontal versions or units that can be fully tilted from horizontal to vertical. An EZ-Tilt feature makes angular adjustments quick and easy. The control panel is on located on an arm that is mounted to a ground post allowing the panel to swivel around the post for flexible positioning.

Related Content

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

Latest Data on Bottled Water Shows Continued Strong Growth

Bottled water’s volume surpassed soft drinks for the first time in 2016 and has done so every year since.

-

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.