New Dual Extruder 3D Printer for Small and Medium-Sized Factory Spaces

It features automatic filament switching to reduce downtime, creating more parts in a compact environment.

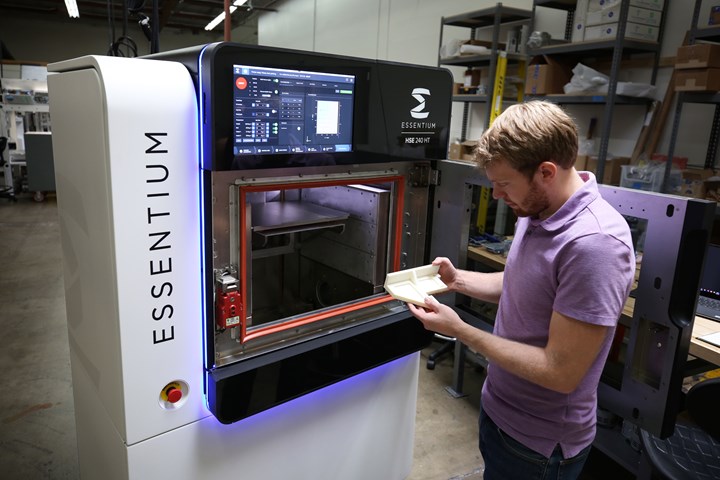

Essentium will debut its newest 3D printing platform, the Essentium High Speed Extrusion (HSE) 240 HT dual extruder 3D printer, at Formnext in November. Featuring a new industrial design including a single dual extrusion print head, the latest addition to the Essentium HSE portfolio is designed to maximize the performance, reliability, and efficiency of parts production — all within a small footprint.

At 1168mm wide x 795 mm deep x 1687 mm high, the HSE 240 3D printer is small enough to fit in small and medium-sized factory spaces and university labs. It features automatic filament switching to reduce downtime, creating more parts in a compact environment. The HSE 240 3D Printer has three print modes that can reportedly create highly accurate parts from different materials in a single print without sacrificing quality and performance.

The Essentium HSE 240 3D printer meets the needs of even the most demanding industries, including aerospace, defense, automotive, and oil and gas, by speeding time to production of complex parts, while significantly reducing post-processing costs, the company stated. As an open material platform, this 3D printer allows customers flexibility in material printing options giving them design freedom to innovate and make their visions a reality.

Essentium HSE 240 3D printer.

Related Content

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.