New Generation of Advanced Plastics Shredding Technology

This technology, called the Beast, is reportedly large enough to efficiently reduce the biggest containers in one operation, and durable enough to last decades.

BCA Industries, Milwaukee, has developed a shredder called “The Beast,” (also known as the ES2000 shredder), which reportedly helps recyclers reliably shred even the largest and toughest plastics to chips at high volumes using unique advances in hydraulic systems.

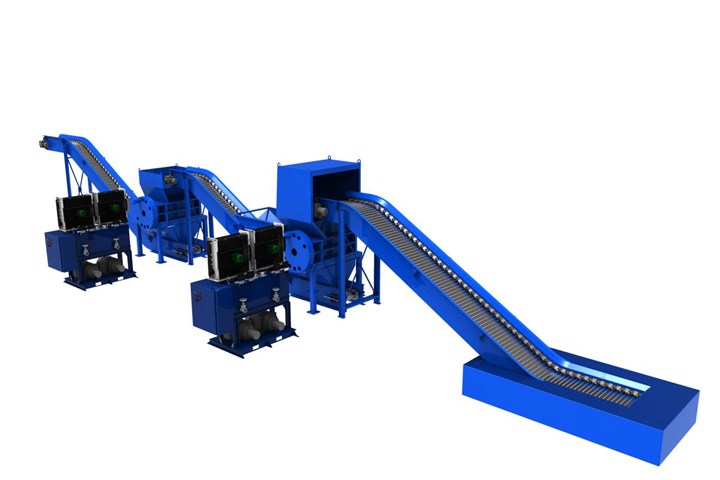

The company says that this unit can shred items like an entire port a-potty or oversize curbside recycling bin thanks to advances in its hydraulic system. The Beast is reportedly large enough to reduce the biggest containers in one operation, and durable enough to last decades. The customizable ES2000 shredder can shred up to 20, 30, and 40 tons/hr in both stationary and portable configurations.

With 24-in. diam hard-faced knives using a base AR-500 alloy, 55 to 72 in. x 44 in. cutting chambers, and 8 in. 4130 Chromoly steel shafts, the unit is designed to shred plastics or dense materials with 179,000 ft/lb of torque per knife. When more throughput is required, it can be rated up to 800 hp, and utilize dual cutting chambers. To maximize high-torque throughput and efficiency, it utilizes a pressure-compensated variable displacement pump that allows the rpm to increase and decrease based on load.

For truly high-volume recycling operations, the size of the shredder can restrict production flow if it is not large enough to accept oversized scrap. Hydraulic shredders operating at a single rpm, using a single rotary piston or gear pump, also never maximize throughput regardless of load.

The lack of robust construction, designed for reducing such materials at high-volume, inevitably leads to breakdowns and unscheduled downtime for repair and replacement. “Typically, shredder companies use 4140 knives, traditional hard-face welding or even tool steel for their systems, but inferior knives increase recyclers’ top maintenance cost—knife rebuilds,” says John Neuens, sales director of BCA Industries.

Neuens says there are a host of other shredder design vulnerabilities that can lead to “catastrophic failures,” if not addressed.

Terry Frank, who worked for Inmetco, an industrial waste and battery recycler, used the Beast to recycle batteries with plastics.

“As production and maintenance supervisor of the largest U.S. industrial battery recycler, I recommended The Beast to ownership in 2012 based on both the cluster drive and variable displacement hydraulic design. The other single-speed shredders we worked with over the years were far too slow for our needs,” he says. “The machine BCA delivered has far exceeded our throughput expectations, doing four times the tonnage and near double the knife life of our other equipment. The downtime has been a small fraction of what we had gotten used to as well.”

Instead of using many shredders to progressively reduce the size of scrap, new shredder “knife” technology like BCA’s patented Triplus system (see New Shredder Knife Technology Can Size in a Single Pass) can uniformly cut to any size in a single pass without a screen, very quickly reducing scrap to a reclaimable proportion. It utilizes a unique bed knife design in a dual shaft shredder to cut the width of the material of the shredder. The size of the end-product is based on the size and geometry of the rotary and fixed knives as well as their gap distances.

A shredder using this design can produce over 85% correctly sized material in one pass with less than 10% oversized material, according to Neuens. He notes that the knife system can reduce scrap to the appropriate size with much less energy than typical shearing and grinding equipment. Power efficiency approaches 150% over any standard shredder.

The customizable ES2000 shredder called "The Beast" from BCA Industries.

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreReversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreRead Next

Designing Recycled Content: How Processors Fit In

Brand owners, material suppliers and processors weigh in on the challenges and opportunities of designing applications with recycled content.

Read MoreU.S. Department of Energy Plans to Provide $14.5 Million to Advance Recycling

Through this funding opportunity, DOE will support a range of projects to develop economically viable solutions for converting plastic films to more valuable materials and design new plastics that are more recyclable and biodegradable.

Read MoreNew Shredder Knife Technology Can Size in a Single Pass

The shredder technology from BCA Industries allows OEMs to simultaneously shred, chip and size on-site.

Read More