New Liquid Materials for Additive Manufacturing

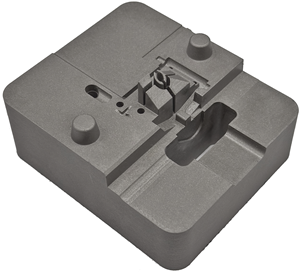

Suited to use in automotive and microelectronic applications, these light-curing epoxy resins have been optimized specifically for industrial 3D printing applications.

Different functional materials (e.g. hard and flexible or transparent and opaque materials) can be combined in one printing process.

DELO, a manufacturer of industrial adhesives for automotive, consumer and industrial electronics applications, sees a bright future for liquid additive manufacturing. Last year, the company announced new developments in liquid materials for this process. DELO says that these materials offer a significant advantage compared to extrusion methods, like filament printing (FDM), because of their isotropic properties.

The new liquid materials crosslink both inside the dispensed bead and between the respective layers of what is being manufactured, with no resultant drop in strength in the z direction (vertical direction of printing).

Tailor-made liquid materials can be made available, based on a broad product portfolio and desired properties, including flexibility, transparency, or conductivity.

“We have liquid material used as our printing material, which can be dispensed at room temperature, so no heating of the component or material is necessary,” said Karl Bitzer, head of product management at DELO. “The advantages with using liquid additive manufacturing and our materials is, that our material cures by light within seconds and you do not only have the chemical reaction within the layers but also between the layers – that means you have a strong and resilient connection between each layer. This brings us to isotropic properties in all printing directions.”

Applied in a laminar flow, the layers are chemically crosslinked, giving rise to homogeneous strengths both inside the material and between the different materials. The result is twofold, with very good adhesion between materials on the one hand, and on the other, no variations in strength according to the printing direction. Layer adhesion inside a printed component is therefore just as good as the cohesion of the material itself.

The functional high-performance materials share a similar chemical basis, and exhibit good adhesion and ideal combinability, making them suitable for material mix. Hard and flexible materials, for example, can be used in one printing process by installing several dispensing heads in a printer, then applying the respective liquid materials according to defined parameters. Depending on the dispensing equipment, structures with wall thicknesses of less than 500 µm are possible using the DELO material. For complex structures with overhangs or undercuts, users can rely on a water-soluble support material.

Since the functional materials are dispensed at room temperature, no heating of the material or installation space is required. Using UV light allows curing within a few seconds. This simplifies the process and helps to save energy.

DELO says that different dispensing heads and curing lamps can be put into the printing machine and combined in the demanded way. This can then be integrated into an existing production line. This allows the printing process to be combined with other manufacturing processes.

“The customer benefits from the possibility to realize material mix parts by combining different high performance materials in one printing job with isotropic strength in all printing directions,” Bitzer said. “Very small functional parts are printable as well as larger ones. It also allows short cycle times and gives design freedom.”

The properties of the cured DELO materials are reportedly comparable to those of high-performance plastics, like polyamide or PEEK, as indicated by the materials' high temperature and media resistances. They are well-suited for applications in the automotive and microelectronic industry, and especially for fine functional structures.

Related Content

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreAdditive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More