New PET Stretch-Blow System Saves Energy & Downtime, Aids rPET Use

New-generation Contiform PET stretch-blow molding machine from Krones is designed for sustainability throughout.

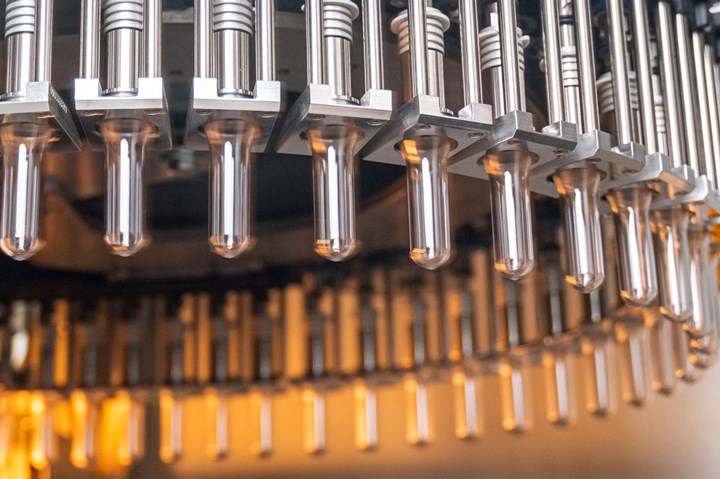

Krones’ Fourth-generation Contiform PET container machine reduces energy for heating and blowing, reduces scrap and downtime, and automatically compensates for rPET variations. (Photo: Krones)

The new fourth-generation Contiform rotary stretch-blow molder from Krones is said to be more efficient, more operator-friendly and more environmentally compatible than ever before. Firstly, it addresses two key factors in energy consumption: heating and compressed-air usage in blowing. The oven has been made more compact, spacing the heaters closer together, and the heaters have been redesigned with parabolic reflectors. The result is 11% lower energy consumption in heating compared with the previous Contiform generation, Krones says.

In addition, the new Air Wizard Triple air-recycling system is a three-stage system that reportedly cuts compressed-air consumption by up to 20%.

And Krones’ new Contiloop AI is an automatic process-control system that uses artificial-intelligence software and newly developed hardware to detect even the slightest variation in material distribution in PET containers and automatically adjusts processing parameters in real time to maintain bottle quality. These capabilities are especially valuable in compensating for variability in rPET raw materials, according to the company.

To top off the “green” features of this machine, the protective panels are made of recycled plastic.

The new Contiform is friendly not only to the environment but also to operating personnel. It features a large-screen interface with the latest touch technology and improved visualization software. Virtual assistants guide operators through setup, even making automatic suggestions.

New “skip-and-run” technology monitors the mold-hanger locking device and allows a blowing station that is not locked—such as because of a defective preform—to pass along the main cam (e.g., to eject the bad preform) without triggering an emergency stop of the entire machine. That considerably reduces scrap, downtime and labor costs.

Related Content

-

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

-

Stretching the Boundaries of Large PET Containers

NPE2024: Cypet shows off new capabilities for its ISBM machines.

-

Coca-Cola’s Redesign of Small PET Bottles Pushes Lightweighting Below Prior ‘Floor’

Coca-Cola thought it had reached the limits of lightweighting for its small PET carbonated soft drink bottles. But a “complete redesign” led to a further 12% reduction.