New Servo-Hydraulic Toggles & Two-Platens from FCS

High-precision, high-speed molding with reduced energy consumption.

Maruka USA is unveiling two new energy-saving servo-hydraulic presses from FCS (Fu Chun Shin), the largest injection machine maker in Taiwan. Making its North American debut is the GenII FA series (35 to 1565 tons) for fast-cycle precision molding. These toggle presses have increased injection pressures and larger tiebar spacing, as well as a KEBA i2880 touchscreen controller.

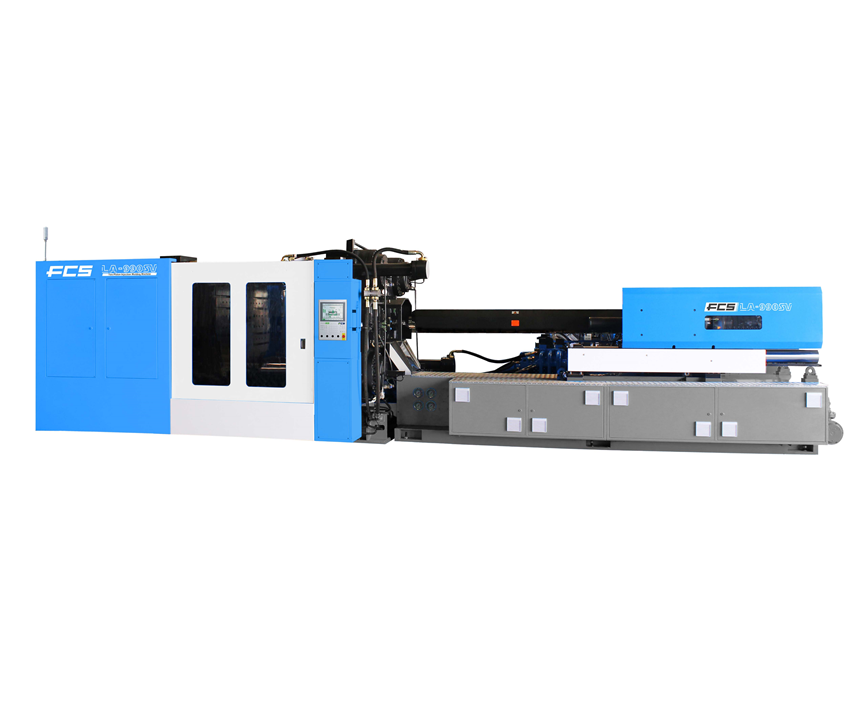

Also new is the LA-SV two-platen series ranging from 560 to 4070 tons. They boast increased clamp speeds and the same KEBA controller as above.

Related Content

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?