Real-Time Mold Monitoring at NPE2024

Progressive Components’ latest mold monitoring platform, the ProFile v4 asset tracking system, is showing actual mold data being collected and managed.

Progressive Components’ (Wauconda, IL) ProFile v4 asset tracking platform for mold monitoring innovation is at NPE2024, giving attendees firsthand demonstrations of actual mold data being collected and managed at Progressive’s booth (W1543).

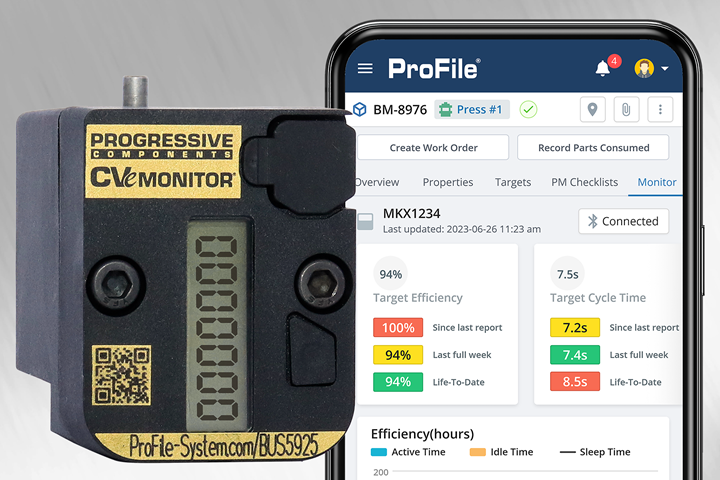

Newly added wireless functionality in ProFile and the Bluetooth-enabled CVe Monitors mounted on injection molds give users real-time insights into production status and key performance indicators. Additionally, ProFile offers preventive maintenance capabilities, facilitates work order management and generates historical OEE data.

At NPE, this capability to wirelessly monitor is demonstrated at Zeiger Industries (W4281), where data is streaming from a CVe Monitor mounted on a mold that was built by M.R. Mold & Engineering and running in a Shibaura machine.

A second live demonstration has real-time data streamed from the Niigata booth (W4161), from a mold provided by Industrial Molds Inc.

Glenn Starkey, president of Progressive Components, notes that the system provides real-time visibility into production, “whether your molds are across the plant or around the world.”

In addition to real-time monitoring, the ProFile system provides asset management, using QR code-enabled asset tags to efficiently retrieve and manage information for molds, presses, fixtures, end-of-arm tooling and equipment.

Attendees can view ProFile asset tags on three tools manufactured by Roembke Manufacturing & Design, operating at the Arburg booth (W3743), Kistler (W3321) and Shin-Etsu (S26055). Additionally, Alliance Specialties and Laser Sales (S31038) is showcasing these asset tags on its laser welding equipment. These asset tags grant authorized personnel access to online file cabinets and enable location tracking through GPS, ensuring meticulous recordkeeping of past locations.

ProFile and the Bluetooth-enabled CVe Monitors mounted on injection molds give real-time insights into production status and key performance indicators. Source: Progressive Components

Related Content

-

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.