Software Promises Synchronous Cross-System Data Analysis for Injection Molding

Kistler says its AkvisIO software offers synchronous, cross-system data analysis for digitally optimized injection molding from a single source.

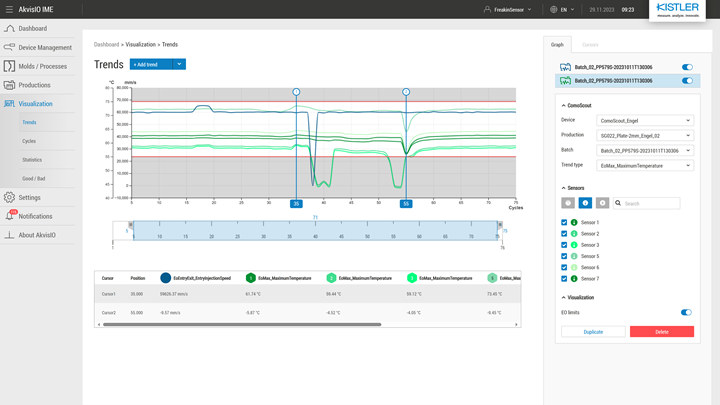

Kistler says its AkvisIO IME (Injection Molding Edition) data analysis software helps digitize injection molding by enabling all data from machines and process monitoring systems, like its ComoNeo and ComoScout units, to be visualized and analyzed synchronously across processes.

Kistler’s AkvisIO IME features data analysis software for recording, storing and analyzing high-frequency sensor and machine signals during injection molding. The technology replaces its former ComoDataCenter (CDC) data management product and provides an analysis function, as well as automatic data synchronization with connected systems.

AkvisIO IME promises seamless integration of ComoNeo and ComoScout systems, so that digital assets like tool configuration, reference curves and monitoring objects can be transferred and managed on the AkvisIO platform and directly on the machine. All data is saved on a cyclical basis and can be compared and analyzed across cycles. Cross-machine and cross-device monitoring of all injection molding processes enables the creation of customized quality assurance reports.

As a modular, scalable software, AkvisIO comes equipped with a number of analysis features that will be continuously expanded. These include the monitoring functions of ComoScout and ComoNeo, known as evaluation objects or EOs, as well as working with reference curves. Other features include cross-cycle trend analysis and statistical process control (SPC) with output of characteristic values for process capability and stability such as cp, cpk, mean value and standard deviation. All analysis data can be visualized and integrated into various reports.

AkvisIO IME data analysis software has been available for the ComoScout process monitoring system since September 2023. This entry-level offering analyzes all available machine signals and works well as a retrofit for the digital connection of injection molding machines that are not yet equipped with mold sensors or those which have sensors that are used for the analysis of temperature signals at voltage inputs.

Starting in January 2024, the data analysis software will also be available for use with the ComoNeo process monitoring system, which monitors the injection molding process utilizing cavity-pressure and temperature sensors.

Customers can tailor the scope of AkvisIO IME based on specific requirements. Additional modules such as trend monitoring with artificial intelligence will be released over time. Users of the previous CDC database can upgrade to AkvisIO, which will be the standard software for ComoNeo and ComoScout as of 2024. Thanks to integrated user management and rights management via lightweight directory access protocol (LDAP), AkvisIO also provides auditing, data security and traceability.

Kistler’s AkvisIO IME will replace the company’s former ComoDataCenter. Photo Credit: Kistler

Related Content

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.