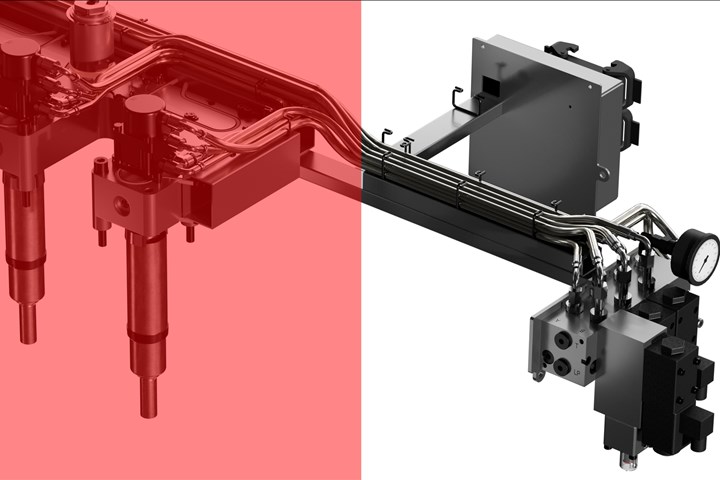

Stroke Regulator for Hydraulically Driven Valve Gate Systems

Oerlikon HRSflow says the new Mechanical Stroke Regulator (MSR) for hydraulically driven valve-gate systems makes it easier to individually preset the pins’ opening positions.

Oerlikon HRSflow has developed a Mechanical Stroke Regulator (MSR) for hydraulically driven valve-gate systems that allows users to preset the opening positions of the pins in hot runner systems. Users can specify the individual oil volumes via a graduated scale adjustment. The valve-gate system can then bring the needles into their intended position. This allows the pressure drop for each nozzle to be set independently, and the pressure distribution during the packaging phase to be controlled.

The MSR is ready-to-install on all of the company’s existing hydraulic cylinder series equipped with electrovalves. Installation can be limited to individual nozzles to save costs, and the company says it only takes around 10 minutes and can be done without dismantling the mold. Modifications to the existing hot runner cutout are not required. If combined with Oerlikon HRSflow’s FLEXspeed system, the speed of the pin can also be adjusted.

Oerlikon HRSflow says that MSR units in the field have proven effective at balancing the melt flow in cascade molding and avoiding surface defects, with numerous trials also demonstrating success in family molds. In a release, the company said management and correct positioning of the pin can eliminate many part defects, with the new MSR making the pressure drop proportional to the opening stroke of the pin.

Oerlikon HRSflow’s new Mechanical Stroke Regulator (MSR) for hydraulic driven valve-gate systems reportedly provides an easy-to-use way to adjust and balance melt flow at different gating points.

Related Content

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

-

How to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.