Automatically Set, Maintain Ideal Cooling Parameters for Temperature Control Units

Engel will use NPE2018 as the North American launch of its iQ flow control software.

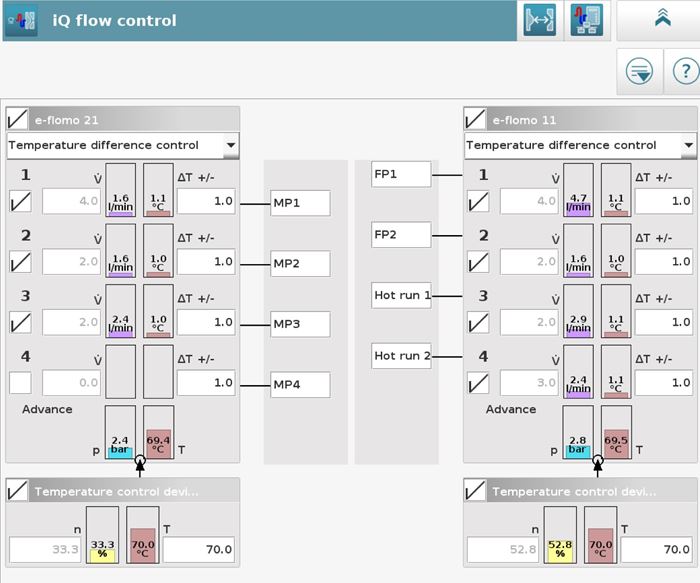

iQ flow control represents Engel’s next step in reducing temperature control errors, building on its flomo electronic temperature control water manifold system and subsequent e-flomo, which automatically set the individually required flow rate for each temperature control circuit.

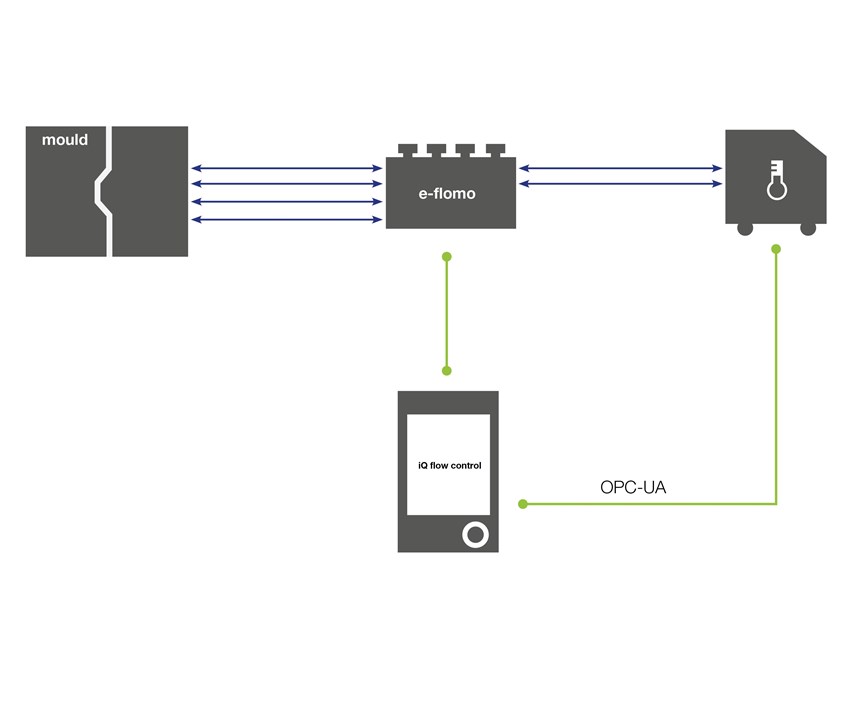

Now iQ flow control software networks the temperature control units and the injection molding machine together, creating, in essence, a single unit. Based on the measured values determined by e-flomo, it controls the pump speed in the temperature control units on demand. While e-flomo increases the process stability and consequently reduces the risk of rejects, automatic speed adjustment means temperature control will require substantially less energy.

Since the pump operates on an on-demand basis rather than at maximum output all the time, stress on moving parts is reduced, giving temperature control units a longer service life. Engel notes that in conventional operations, regular maintenance, which requires downtime, can be a major cost factor.

In operation, the entire temperature control process can be set up, monitored and logged on the Engel press’s CC300 machine control. The control determines the ideal operating point for the temperature control unit and sets it automatically.

To integrate the temperature control units with the CC300 control unit on the injection molding machine, Engel collaborated with temperature control unit manufacturer HB-Therm (St. Gallen, Switzerland), to develop the temperature control unit series known as e-temp. The compact devices are networked with the press via OPC UA protocol.

Related Content

-

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.