Thousandths Increment Core Pin Line Expanded

Progressive Component’s line of TI Pins now includes 267 standard sizes in new, longer lengths.

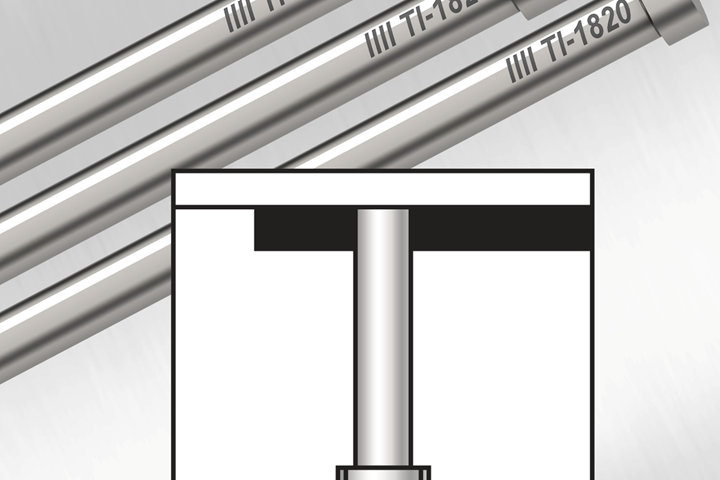

Designed to fit into small, crowded cavity and core inserts, Progressive Component’s TI Pins are manufactured with hardened M-2 steel and available in diameters from 0.060 to .320" in both 2.5 and 5.5" lengths. Progressive notes that cut-to-length and custom options beyond those are also available.

As opposed to stamping punches, which are sometimes used as core pins in molds, Progressive says its TI Pins feature heads that are precision ground to mold tolerances. Also, rather than beginning with a fractional-diameter core pin, step grinding can be eliminated with tool inserts precision cut to the molded part diameter via wire EDM. Doing so means the TI Pins only need to be cut to their finished length.

Progressive Component’s TI Pins are manufactured with hardened M-2 steel. Source: Progressive Components

Related Content

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.