TOOLING: New Developments in Tooling For In-Mold Assembly

Multiple rotating plates index in and out of the mold to produce parts with up to six materials.

A new partnership between French and American toolmakers has facilitated broader access to sophisticated tooling concepts for multi-material overmolding, in-mold assembly, injection-blow molding, and multilayer injection of thick optical lenses. Some recent applications demonstrate the extreme versatility of the system. What’s more, these patented tooling capabilities have been enhanced with new developments for LSR and heat/cool molding.

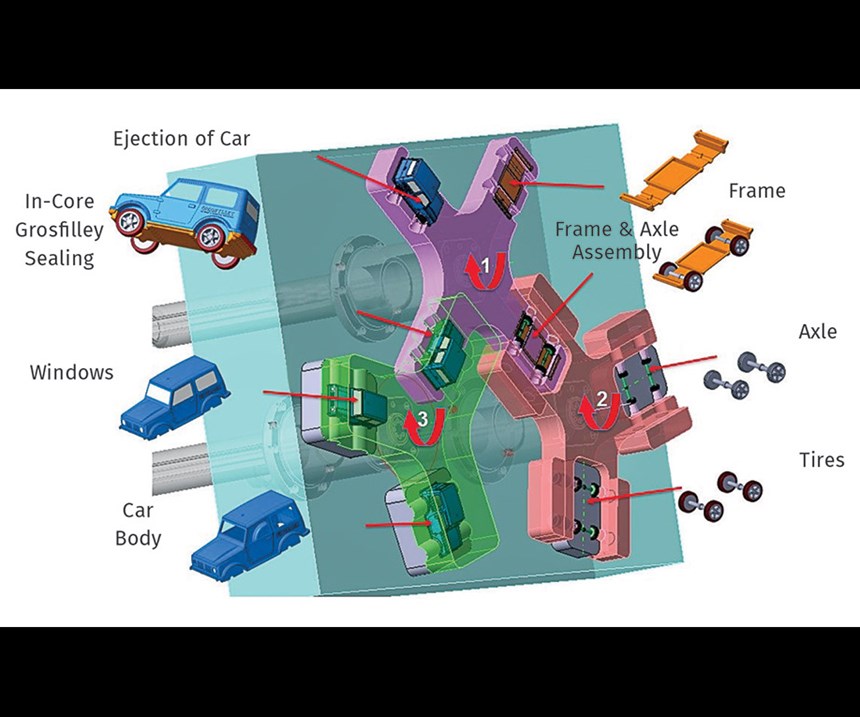

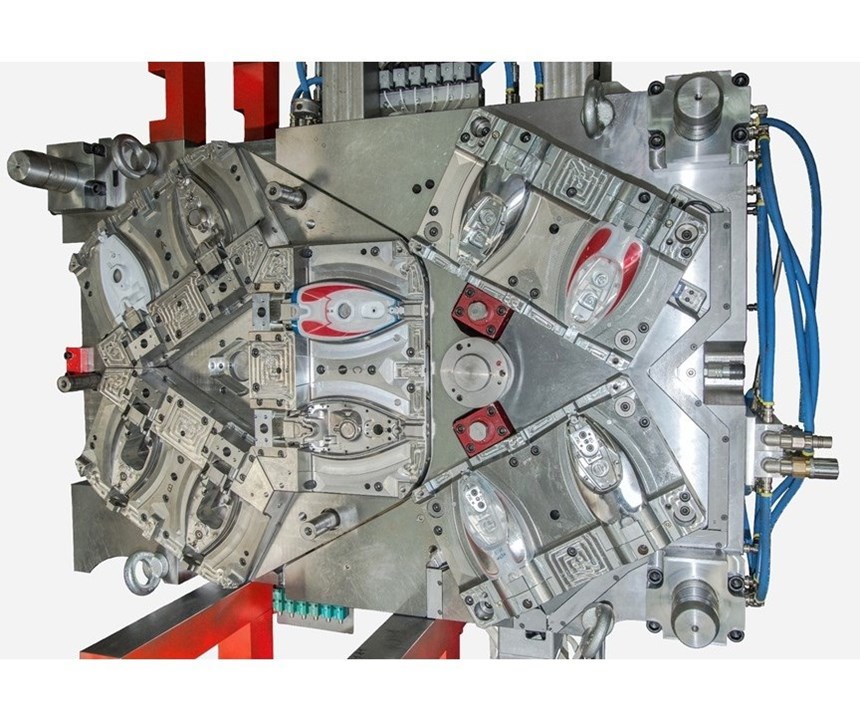

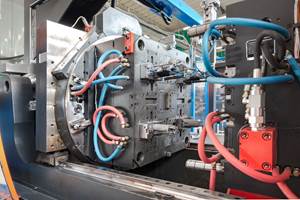

French toolmaker JP Grosfilley SAS, specializing in multi-shot molds, has partnered with medical mold builder X-Cell Tool & Mold Inc., Fairview, Pa., as its representative in North America. While some companies have developed rotary-stack, or “cube” molds for multi-component molding, Grosfilley’s approach to multi-shot molding is different: It uses rotating Index Plates on a single parting line to permit multiple consecutive functions—such as injection overmolding, cooling, in-mold assembly, injection in “hidden time” and even injection-blow molding—all within a single shot and without extending cycle time.

Grosfilley has built molds with one, two, or even three rotating elements. Those elements not only rotate by 90°, 120°, or 180° on each cycle, but the elements can index out from the mold base before rotating, so as to transfer parts from one rotating component to another for overmolding and in-mold assembly. That way, parts composed of up to six components (and more in development) can pass through up to 10 stations on a single mold face.

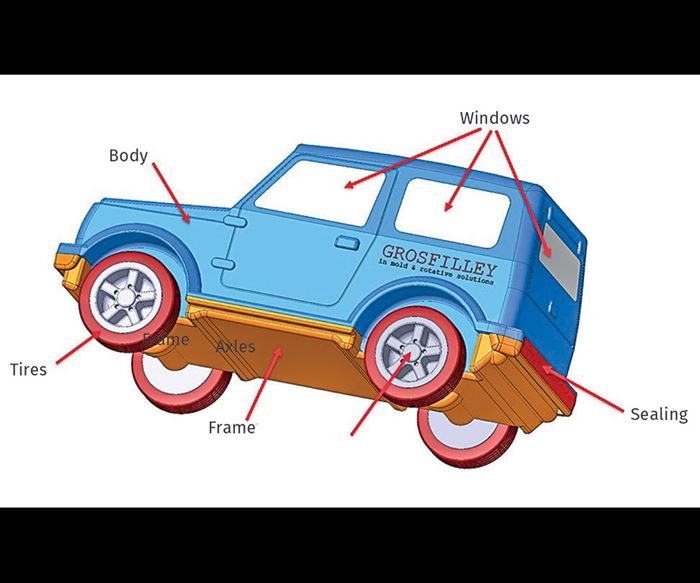

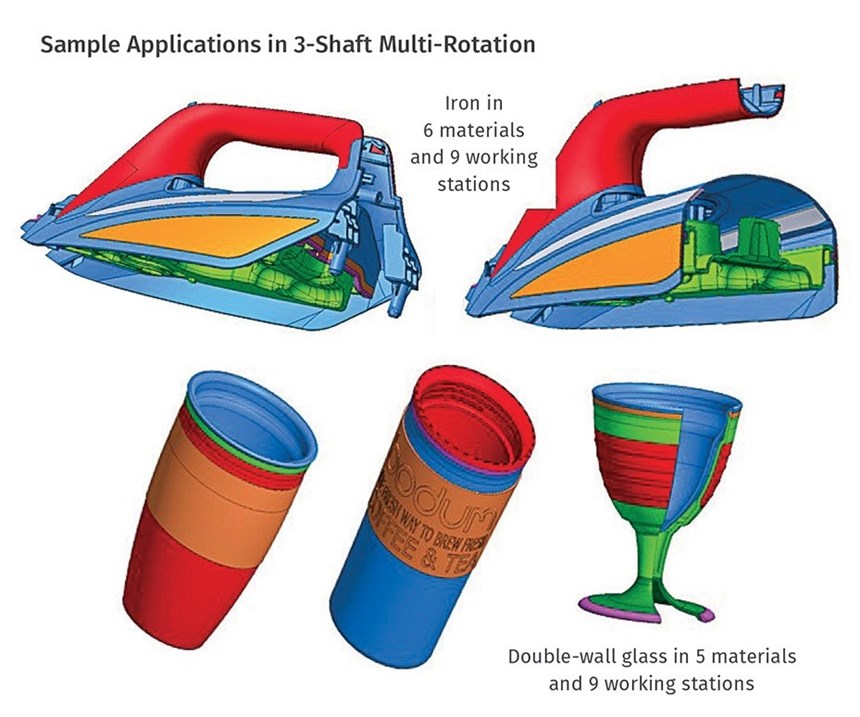

Several recent applications are cited by Philippe Gaudin, innovations and R&D manager for Grosfilley. One is a toy car molded with six materials—clear and colored PP, TPO, and styrenic TPE—in nine stations with three rotating elements (see Figs. 1 & 2). Another is a steam iron from Rowenta in Germany, consisting of six materials—PP and TPO in different colors—again with nine stations using three rotating elements (Figs. 3 & 4). That iron formerly required 12 people for assembly, now reduced to three, and a single injection machine. An overall scrap rate of 10% in the past has been reduced to zero with the Grosfilley system. In addition, a double-walled drinking glass utilizes five materials in nine mold stations (Fig. 3).

Newer developments from Grosfilley include molding thick optical lenses in multiple shots of the same material, and injection-blow molding on a standard injection machine, with injection and blowing taking place in different stations. This was demonstrated by Wittmann Battenfeld (U.S. office in Torrington, Conn.) on one of its machines at the K 2016 show. In addition, the new “Supercharged” range of Grosfilley Index Plates can rotate cores or cavities weighing up to 12 tons with 0.01° accuracy. The Supercharged range also can handle higher temperatures—up to 200 C/392 F—for overmolding LSR on thermoplastic or vice versa.

Gaudin reports that another new development improves heat/cool molding in larger molds with multiple gates and long flows. The key is electrically conductive ceramic mold inserts positioned a few millimeters behind the cavities. They provide rapid, pinpoint heating control, which is paired with conformal cooling channels close to the cavity as well. One result, Gaudin says, is that the melt stays hotter until the end of flow, so that when flow fronts merge, less of a weld line is produced. Gaudin also notes that Grosfilley can build tools with independent water circuits plumbed through the central shaft of rotating mold components.

X-Cell Tool will exhibit its capabilities for designing and building medical molds at NPE2018 May 7-11 in Orlando, Fla. (Booth S10166). A Grosfilley mold will run on a new model of injection machine at the booth (W2703) of Cincinnati-based Milacron, Inc., in a system together with a Mold-Masters hot-runner system and E-Multi auxiliary injector. The mold will utilize a G2 index-plate system. The product will be a two-component drinking glass.

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreCoinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More