‘Universal’ Structural Foam Nozzles And Manifold Components

Wilmington now provides these components for all makes of structural-foam machines.

For the first time, Wilmington Machinery is now offering structural-foam nozzles and manifold components that are said to be “universal” for all structural-foam machines of any make. Previously, the company offered such components only for its own machines. The new Lumina products, all manufactured in-house, are available on the company’s website and sold as assemblies or individual components.

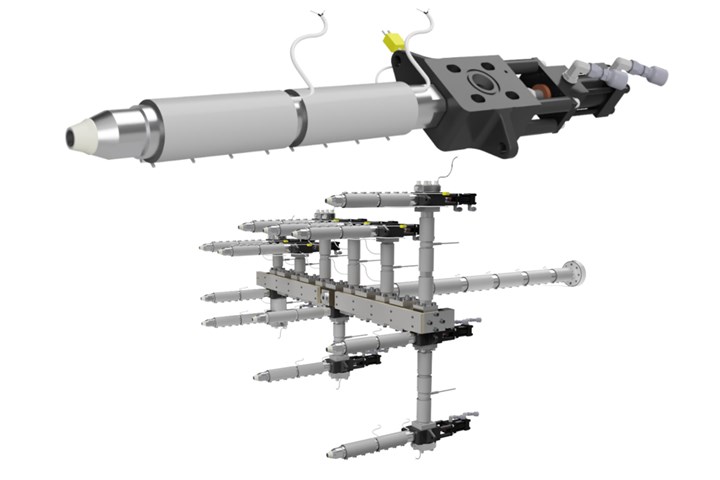

The Lumina nozzle has a forged body with what are described as “generous flow characteristics” and variable nozzle length extensions. The forged nozzle housing is said to provide improved plastic flow compared with other nozzle types. It also reportedly costs less than comparable nozzles. The Lumina manifolds are provided with block-off plug provision to eliminate stagnant melt buildup. Spacers (manifold extensions) are available in various lengths to match the 6 × 6 in. grid pattern for nozzle placement.

Related Content

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.