Updated Controls Make Feeders 'Smart'

Control package provides foundation for Industry 4.0 and predictive maintenance.

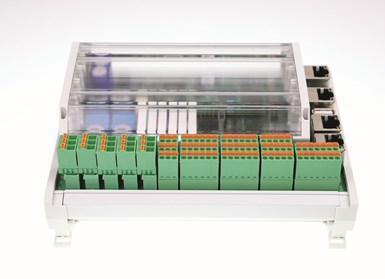

Brabender Technologie’s next generation of feeders controller, the Congrav CM-E 3.0 and Congrav CB-E 3.0, are said to provide a high-performance foundation for the future in which the Internet of Things (IoT), predictive maintenance and equipment monitoring will play major roles.

The new controller features multiple advanced RISC processors. These processors form the basis of an energy-efficient, high-performance platform and provide the necessary computational power to enable a high level of feeder performance required in today’s and tomorrows demanding industrial environments the company says. Two main processors (CPUs) with five cores ensure fast and efficient communication as well as computational and distribution processes. The software has been designed for easy upgrades to make the best use of the new hardware platform.

The new control modules feature six digital inputs and six digital outputs, more than any previous generation of controllers. The inputs can be used for stop/start functions or interlocks, while the outputs can be used for operating, refilling (for instance via a slide gate above the feeder), or for alarm messages.

The new controller provides multiple state of the art ethernet interfaces. It will be possible to connect two network socket connection terminals using a second new TCP (Transmission Control Protocol) network protocol interface. The controller can bi-directionally share data with other computers using this new link.

A “realtime clock” has been incorporated in the new Congrav CB-E controller that even operates when the controller is turned off. It provides accurate activity information and aids in feeder diagnosistics and predictive maintenance. A total of four ethernet interfaces provide extra capacity for future IoT tasks, host interfaces, diagnosistics, maintenance or connection to the operator control unit. Having up to 63 modules for controlling external add-ons substantially increases the possible options. A mini-PCI express slot and slots for future add-in cards, like WLAN or Bluetooth modules, were also incorporated in the design. The new generation of controllers can be operated using the existing Congrav® OP1-S (for one feeder), Congrav® OP6-E (for a maximum of six feeders) or Congrav® OP16-E (for a maximum of 16 feeders) operator interfaces. Backward compatibility is built in for most previous generations of Brabender Technologie controllers and operator interfaces.

Related Content

-

Precise Blender for Low-Throughput Molders

NPE2024: Gravimetric batch blender precisely delivers precise material blends from up to four ingredients at extremely low throughputs.

-

Finding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

-

ACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.